Yuav Ua Li Cas Xam Lub Zog Tuag Casting Tonnage

Muab xam cov mis

Lub tswv yim muab xam rau kev xaiv lub tshuab tuag-casting: Tuag-casting tshuab clamping quab yuam (t) = 1.4 * casting cheeb tsam thaj tsam * piv ntawm thaj chaw npaj ntawm qhov tuag-qhov orthographic npaj thaj tsam ntawm qhov tuag casting * tsim qauv (CM2).

Lub tonnage ntawm lub tshuab tuag-casting yog qhia los ntawm clamping quab yuam ntawm lub tshuab.

Txij li cov tuag-casting alloy raug xuas nrig ntaus hauv "kev kub ceev thiab siab-siab" hauv lub xeev, yog tias lub tshuab tuag-khawm tsis nruj, lub zog ua kom ya dav hlau yuav tshwm sim, ua rau zais kev phom sij ntawm kev ua haujlwm raug mob, qhov chaw ntxhov thiab tsis zoo ntawm castings.

Cov lus xam muab rau kev xaiv ntawm lub tshuab tuag-casting rau qhov tuag-casting qhov chaw yog li nram qab no:

- Tuag-casting tshuab clamping quab yuam (t) = 1.4 * casting cheeb tsam ua haujlwm * tshwj xeeb siab

- Nruag yees qhov chaw-orthographic npaj thaj tsam ntawm qhov tuag casting * qauv (CM2)

Yog tias koj xaiv lub tshuab tuag-tshuab cais raws li qhov hnyav lossis loj

Koj tuaj yeem ua qhov no:

Qhov Loj: Feem ntau qhov chaw casting ntawm cov khoom lag luam (suav nrog cov txheej txheem), chav tsev yog xam rau hauv cm, muab faib los ntawm 2.5, thiab daim duab tau txais yog qhov tsawg kawg nkaus tonnage yuav tsum tau ua.

Qhov hnyav: Nws yog qhov yuav tsum paub cov khoom ntim ntau tshaj plaws ntawm lub tshuab. Ntau lub tshuab ntsuas tsis sib txawv ntawm qhov tseeb tshuab teeb tsa ntawm cov khoom siv yeeb nkab thiab lub tshuab ua kua zaub. Piv txwv, theoretical pouring ntim ntawm 1250 tons yog 13-25.4kg. Qhov tseeb, ntau lub tshuab tuag-tsuas yog muaj qhov ntim ntau ntawm 10-12kg; lub Hoobkas ntsuas ntawm 1600 tons yog 17-32kg nchuav ntim, uas yog txog 16-20kg (nyob ntawm txhua lub Hoobkas kev teeb tsa).

Lub tonnage ntawm lub tshuab tuag-casting yog lub zog clamping ntawm lub tshuab tuag-casting, tsis yog lub zog clamping. Lub zog clamping ntawm lub tshuab tuag-qhov tuag tau pom tau hais los ntawm lub zog clamping ntawm lub clamping lub tog raj kheej thiab cov toggle quab yuam nthuav dav tshuab, tsis yog lub zog ntawm clamping lub tog raj kheej. Raws li rau qhov tonnage ntawm lub tshuab tuag-casting, nws muaj feem xyuam rau tag nrho cov chaw pov tseg ntawm qhov chaw tuag-qhov chaw ua haujlwm (suav nrog thaj chaw npaj ntawm qhov chaw tuag-casting, slag hnab, hla khiav, qe thiab ncuav mog qab zib) ), nws yog qhov zoo tshaj plaws los xam qhov tseeb thaj chaw siv tsis txhob siv coefficient. Vim tias cov khoom sib tshooj ntawm cov ntu loj tsis tuaj yeem siab dhau, thiab cov khoom lag luam ntawm cov khoom me me yog siab dua, nws yog qhov tseeb dua los xam lub zog clamping raws li qhov tseeb kwv yees thaj tsam ntawm pwm. Raws li rau qhov kev xaiv ntawm casting siab, nws nyob ntawm qhov nyuaj ntawm cov casting, feem ntau li ntawm 500bar mus rau 800bar.

Txij li cov tuag-casting alloy raug xuas nrig ntaus hauv "kev kub ceev thiab siab-siab" hauv lub xeev, yog tias lub tshuab tuag-khawm tsis nruj, lub zog ua kom ya dav hlau yuav tshwm sim, ua rau zais kev phom sij ntawm kev ua haujlwm raug mob, qhov chaw ntxhov thiab tsis zoo ntawm castings.

Yog li no, lub tshuab tuag-tshuab tuaj yeem muab tau 160t pwm lub zog, thiab lub tshuab tuag-hu ua 160t.

Kev Ua Haujlwm Kev Ntsuam Xyuas Ntawm Lub Cav Tuag Tuag Casting Tonnage

Kuv cov khoom yog xx grams thiab qhov loj yog xx * xx hli. Kuv siv lub tshuab loj npaum li cas los luam tawm nws? "——Qhov no yog qhov teeb meem ib txwm nyob hauv kev xaiv ntawm lub tshuab tuag-casting tuag-tshuab.

Kev xaiv ntawm kev tuag casting tshuab ntxhib nrog peb peb yam:

- 1. Lub tonnage ntawm lub tshuab tuag-cuam tshuam ntsig txog seb cov khoom yuav ya

- 2. Pwm loj, uas cuam tshuam seb pwm puas tuaj yeem ntsia ntawm lub tshuab tuag casting

Tso nyiaj npaum li cas, uas cuam tshuam txog seb cov khoom lag luam tuaj yeem ua tau zoo li cas

Li cas los xam cov khoom tshuab tonnage?

Hais txog qhov teeb meem ntawm suav qhov tonnage ntawm lub tshuab tuag-tshuab, nws tsis yooj yim hais tias nws tsis nyuaj, tab sis nws tsis yooj yim hais tias nws yooj yim. Tsuav koj to taub qhov kev sib raug zoo, nws yog ib qho yooj yim los laij lub tshuab tonnage uas xav tau rau cov khoom.

Thawj txiav txim siab xws li lub tswvyim

Lub tonnage ntawm lub tshuab tuag-casting hais txog lub zog clamping ntawm lub tshuab tuag-casting

Clamping quab yuam yog thawj kis tau txiav txim siab thaum xaiv lub tshuab tuag casting. Lub luag haujlwm ntawm lub zog clamping feem ntau yog kom kov yeej lub zog loj hauv cov kab noj hniav, txhawm rau txhawm rau pwm, tiv thaiv pwm hlau tsis tuaj yeem txaws, thiab ua kom lub qhov ntev ntawm qhov ua haujlwm ntawm casting.

Yog li rov qab mus rau lo lus nug thawj, yuav ua li cas los xam lub zog clamping ntawm lub tshuab tuag casting? Thawj saib cov qauv hauv qab no:

Tuag-casting tshuab clamping quab yuam> pwm qhib quab yuam F1 × 1.1

Yog li, dab tsi yog cov pwm qhib kev quab yuam thiab yuav ua li cas los xam nws?

Pwm qhib lub zog yog hais txog lub zog ua rau ntawm lub tshuab ua kom lub pwm kom nthuav dav thaum tuag casting ntau lawm. Cov pwm qhib lub zog tuaj yeem tau los ntawm cov qauv hauv qab no:

Qhov chaw casting × casting siab

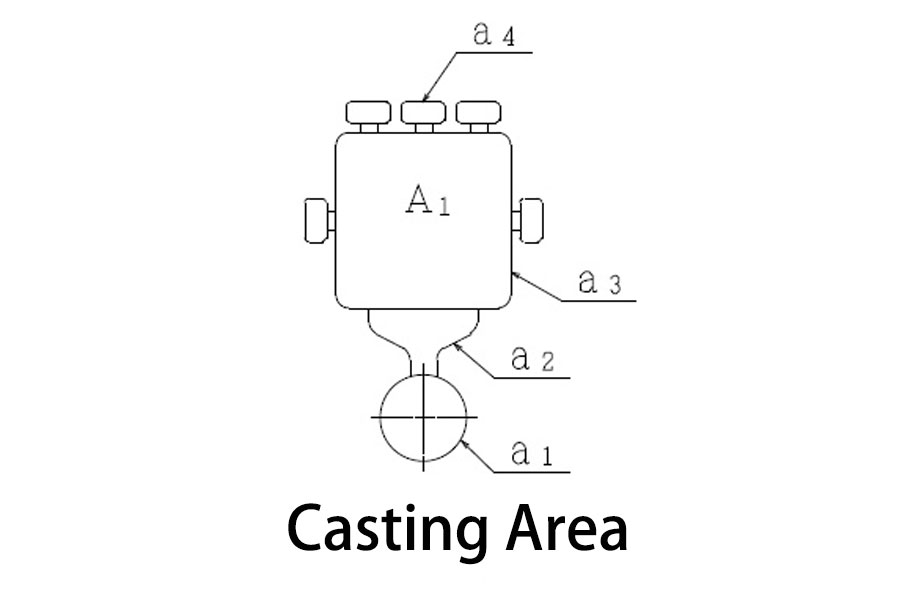

Cov chaw ntim khoom A1 = a1 + a2 + a3 + a4 = thaj chaw ncuav mog qab zib + thaj chaw khiav + thaj chaw cov khoom + thaj tsam hnab

Kev kwv yees hauv cheeb tsam Thaum cov pwm tsim tsis tiav, peb tsuas yog paub thaj tsam npaj a3 ntawm cov khoom, thiab kwv yees nws

- a2 = 0.21a3

- a4 = 0.12a3

Thaj chaw ntawm lub ncuav mog qab zib yog ua raws li punch

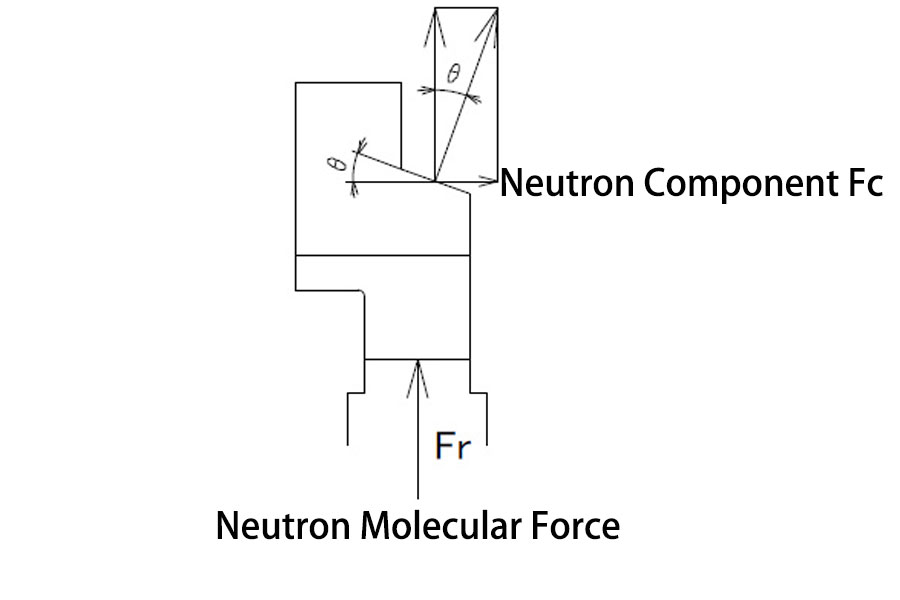

Pwm qhib lub zog F1 = casting siab Pp × casting cheeb tsam A1 + neutron tivthaiv quab yuam Fc (kev suav lub pwm qhib lub zog nrog lub nplauv)

Thaum muaj cov nplais qis neutrons, neutron lwg me me xav tau xam

Neutron rov qab quab yuam Fr = cov khoom hauv thaj av Ac × laij casting siab × 75%

Neutron tivthaiv quab yuam Fc = neutron rov qab quab yuam Fr × tanθ

Mold opening force F1=(a1+a2)×Pp+a3×Pp×0.75+a4×Pp×0.25+Fc

Casting siab faib:

Vim tias qhov ntsuas kub ntawm cov pwm tsis tsim nyog thiab lub siab xa mus tsis sib thooj, lub siab thov rau txhua ntu raug cais thiab suav raws li hauv qab no:

- Khoom department = xam casting siab × 75%

- Slag hnab ntu = suav casting casting siab × 25%

- Ncuav mog qab zib, khiav ib feem = xam casting siab × 100%

Xam siab kwv yees:

Aluminium: Cov huab cua nruj yuav tsum yog siab tshaj 80MPa, lwm yam 60MPa

Zinc: txog 30MPa

Lub zog clamping yuav tsum yog 1.1 npaug lossis ntau dua ntawm cov pwm qhib quab yuam. Yog tias pwm qhib lub zog loj dua lub clamping quab yuam, flashing (luv luv txhaj) thiab loj dua li yuav tshwm sim, thiab qhov tseeb ntau lawm tsis tuaj yeem nqa tawm.

Hauv cov ntsiab lus, zaum kawg xam mis ntawm tuag casting tshuab tonnage tuaj yeem tau txais:

Clamping quab yuam> pwm qhib lub zog × 1.1 = qhov chaw casting × casting siab = (thaj chaw ncuav mog qab zib + khiav thaj tsam + thaj chaw cov khoom + thaj tsam lub hnab pob) × casting siab × 1.1

Tuag casting tshuab tonnage = clamping quab yuam / 10, clamping quab yuam yog KN

Thov khaws qhov chaw thiab qhov chaw ntawm tsab xov xwm no kom luam tawm: Yuav Ua Li Cas Xam Lub Zog Tuag Casting Tonnage

Minghe Casting Lub Tuam Txhab tau mob siab rau kev tsim khoom thiab muab cov khoom zoo thiab ua haujlwm siab Casting Hlau (hlau tuag casting qhov chaw ntau yam suav nrog) Nyias-Ntsa Tuag Casting,Kub Chamber Tuag Cuam Hlav,Cold Chamber Tuag Casting), Kev Pab Hloov (Txoj Kev Tuag Casting,Cnc Machining qhov chaw,Pwm Tsim, Nto Kho) .Txoj kev cai Aluminium tuag casting, magnesium lossis Zamak / zinc tuag casting thiab lwm yam kev xav tau castings zoo siab txais tos hu rau peb.

Raws li kev tswj hwm ntawm ISO9001 thiab TS 16949, Tag nrho cov txheej txheem tau ua los ntawm ntau pua tuag lawm cov tshuab ua haujlwm tuag, lub tshuab 5-axis, thiab lwm qhov chaw, suav txij li blasters mus rau Ultra Sonic tshuab ntxhua khaub ncaws.Minghe tsis tsuas muaj cov cuab yeej siv siab heev tab sis tseem muaj kev tshaj lij pab neeg ntawm cov paub txog cov engineers, cov neeg ua haujlwm thiab cov kuaj xyuas kom ua tau cov neeg siv khoom tsim.

Daim ntawv cog lus chaw tsim khoom ntawm cov tuag castings. Kev muaj peev xwm suav nrog txias chamber txhuas tuag casting qhov chaw ntawm 0.15 lbs. rau 6 lbs., kev hloov ceev teeb, thiab machining. Cov kev pabcuam muaj txiaj ntsig suav nrog kev ua polishing, vibrating, kev tawm tsam, tua phom, pleev xim, plating, txheej, sib dhos, thiab tuam. Cov ntaub ntawv ua haujlwm nrog nrog cov alloys xws li 360, 380, 383, thiab 413.

Zinc tuag casting tsim kev pab / kev pabcuam engineering ua ke. Kev cai chaw tsim tshuaj paus ntawm precision zinc tuag castings. Tej yam me me castings, kev kub siab tuag castings, ntau zaws castings, cov pwm ua kom yooj yim nrum, chav tsev tuag thiab ywj siab tuag castings thiab kab noj hniav castings tuaj yeem tsim tawm. Castings tuaj yeem tsim nyob rau hauv qhov ntev thiab dav li 24 in. Hauv +/- 0.0005 in. Kam.

ISO 9001: 2015 daim ntawv pov thawj chaw tsim khoom ntawm cov tuag nrum magnesium, Muaj peev xwm suav nrog kev kub siab magnesium tuag casting li 200 tuj kub chav & 3000 tuj txias chav, tsim qauv tsim, polishing, molding, machining, hmoov & kua pleev xim, tag nrho QA nrog CMM lub peev xwm , sib dhos, ntim & xa khoom.

ITAF16949 muaj ntawv pov thawj. Kev Pab Cuam Ntxiv Ntxiv Muaj Xws Li peev casting,xuab zeb casting,Lub ntiajteb txawj nqus Casting, Poob Ua Npuas Ncauj Casting,Centrifugal Casting,Nqus Plua Plav Casting,Permanent Mould Casting, .Cov kev ua haujlwm tau suav nrog EDI, kev pabcuam hauv engineering, kev ua qauv zoo thiab kev ua theem nrab.

Casting Kev lag luam Cov Khoom Siv Kev Tshawb Fawb Txog: Cov Tsheb, Tsheb kauj vab, Cov dav hlau, Cov twj paj nruas, Dej nkoj, cov khoom siv hluav taws xob, cov pa hluav taws xob, Cov qauv, Cov khoom siv hluav taws xob, cov khoom thaiv, Lub moos, cov tshuab, cav, Rooj tog, Nyiaj-kub, Jigs, Telecom, Teeb pom kev zoo, cov cuab yeej kho mob, Duab thaij duab, Kev Kho Mob Hlau, Duab puab, Khoom siv suab, Khoom siv ntaus pob ncaws pob, Cuab yeej siv, Cov khoom ua si thiab lwm yam.

Dab tsi peb tuaj yeem pab koj tom ntej?

Mus Rau Homepage Rau Tuag Ua Si Suav Teb

→Qhov chaw cam khwb cia-Qhia saib peb tau ua dab tsi.

Tips Hais Txog Ralated Cov Tuag Ua Ke Cov Kev Pab

By Minghe Tuag Casting Chaw tsim tshuaj paus | Pawg: Cov Lus Tseem Ceeb |khoom Tags: Txhuas Casting, Zinc Casting, Hlau nplaum, Titanium Casting, Stainless Hlau Casting, Tooj dag Casting,Bronze Casting,Khawb Ua Yeeb Yam,Tuam txhab keeb kwm,Txhuas Tuag Casting Lus tawm