Bronze Casting

Bronze Casting Cov Kev Pab Cuam - Nchuav Casting Bronze Alloy Chaw Tuam Txhab Tuam Txhab

IATF 16949 CERTIFIED CAST ROOJ RAUG RAU BRONZE CASTINGS

Bronze Casting Yog Dab Tsi? Lub sijhawm thaum ub Suav nyob ntawm cov tooj dag yog pib ua los ntawm tej tooj liab. Hauv Ntxog Xaj Ntxov thaum ntxov, nws muaj peev xwm siv hluav taws kub los ua tooj dag ua los ntawm tooj liab-tin alloy. Tam sim no, txoj kev paub txog kev tsim cov khoom qub ntawm cov qauv suav hauv Suav teb feem ntau yog siv cov kiv cua casting txoj kev, thiab ib qho me me ntawm tooj dag nrog cov qauv tsis yooj yim thiab cov qauv nyuab kuj yog siv los ntawm cov qauv siv quav ciab, txoj kev casting, txoj kev vuam, thiab lwm yam kev sib txawv ntau lawm yuav tawm cov cim sib txawv ntawm cov tais diav.

Nrum tooj dag thaum chiv thawj tsuas yog raug xa mus rau tin bronze. Tom qab ntawd, vim kev coj los ua ntau yam ntawm cov ntsiab lus alloying, hom tshiab ntawm tooj dag uas tsis yog tin tin tshwm sim, xws li txhuas bronze, silicon bronze, manganese bronze, chromium bronze, beryllium bronze thiab tooj bronze.

Cov tooj dag yog tooj liab siv los ua cov hlau nplaum. Bronze castings yog siv dav hauv kev siv tshuab, nkoj, tsheb, kev tsim kho thiab lwm yam kev lag luam, tsim kev ua cov tooj dag tooj liab hauv cov khoom siv hlau tsis hnyav. Feem ntau siv cov npluav pob zeb tooj yog tooj liab bronze, txhuas tooj liab, manganese bronze thiab txhuas bronze.

Xav tau cov khoom siv tooj dag los ntawm ib qho kev paub thiab txhim khu kev qha ntau lawm pawg khoom lag luam? Minghe yog Tuam Tshoj sab saum toj casting ntau lawm thiab tsim cov tuam txhab, muab kev pabcuam zoo tshaj plaws ua rau bronze casting, thiab muaj qhov zoo tshaj kev cai casting ntawm tooj dag rau kev siv khoom xws li cov khoom siv hluav taws xob, kev kho mob, zaub mov, semiconductor, tshuab, tsheb, tsheb thauj mus los thiab lwm yam. Nrog ntau dua 35 xyoo ntawm kev paub, peb muaj cov kws tshaj lij thiab kev tsim khoom tsim los tsim precision kev cai bronze qhov uas yuav ua tau raws li koj tshaj li koj daim ntawv thov. Peb tseem muaj lub peev xwm los muab cov tooj dag ntawm cov tuag casting, peev casting, xuab zeb casting, tuag-txiav, sib tsoo, khoov, CNC tshuab, thiab vuam.

Hu rau peb cov bronze casting feem engineer niaj hnub no los tham txog qhov tshwj xeeb ntawm koj cov phiaj xwm nyuaj.

Cov Zaj Duab Zaum Ntawm tooj tooj cua

Qhov ntim tsawg dua ntawm Cu-Sn alloy yog tsawg heev (linear shrinkage tus nqi yog 1.45% ~ 1.5%), thiab nws yog qhov yooj yim los tsim cov nruas nrhav nrog cov qhov ntev thiab cov khoom siv tes ua haujlwm nrog cov qauv pom tseeb. Casting tin tin feem ntau ntxiv cov ntsiab lus xws li zinc, txhuas, thiab phosphorus. Phosphates muaj lub siab hardness, hnav tsis kam, thiab cov khoom zoo abrasive. Hauv cov coj-resistant tin tooj liab, phosphorus cov ntsiab lus yuav ua tau kom siab npaum li 1.2%. Zinc tuaj yeem txhim kho qhov kev npliag ntawm cov xaim thiab txo cov txheej txheem los tiv thaiv kev sib cais ntawm cov tooj liab. Lead ua txhim kho qhov hnav tsis kam thiab kev siv tau ntawm qhov ua ke. Kev siv cam khwb cia tin bronze yog siv ua qhov hnav-resistant thiab corrosion-resistant qhov chaw.

- - Cov phosphor tooj dag. Phosphorus yog qhov zoo deoxidizer rau cov tooj liab alloys, tuaj yeem txhim kho qhov kev npliag ntawm cov alloy, txhim kho cov txheej txheem thiab cov cuab yeej muaj zog ntawm tin bronze, tab sis nce qib ntawm thim rov qab sib cais. Qhov kawg solubility ntawm phosphorus nyob rau hauv tin tooj dag yog 0.15%. Thaum nws ntau dhau, α + δ + Cu3P ternary eutectic yuav tsim, nrog yaj ib qho ntawm 628 mel. Nws yog qhov yooj yim los tsim kub brittleness thaum kub dov thiab tuaj yeem tsuas yog ua haujlwm txias. Yog li ntawd, cov phosphorus cov ntsiab lus hauv cov yeeb yaj kiab uas tsis sib cais yuav tsum tsis txhob ntau dua 0.5%, thiab cov phosphorus yuav tsum tsawg dua 0.25% thaum ua haujlwm kub. Phosphorus-muaj cov tin bronze yog cov ntaub ntawv zoo-elastic. Thaum lub sijhawm ua zaub mov, nws yog qhov yuav tsum tswj cov qoob loo loj ua ntej txias ua haujlwm thiab kub kub annealing tom qab ua tiav. Lub zog, elastic modulus thiab qaug zog lub zog ntawm cov khoom ua tiav tau zoo yog siab dua li ntawm cov coarse-grain tiav cov ntaub ntawv, tab sis cov khoom yas yog qis dua. Cov khoom siv ua haujlwm txias yog annealed ntawm qhov kub tsawg ntawm 200-260 ° C rau 1 mus rau 2 teev los tsim cov annealing hardening nyhuv, uas tuaj yeem txhim kho ntxiv lub zog, yas, elastic txwv thiab elastic modulus ntawm cov khoom, thiab nce ruaj ntseg ntawm elasticity.

- - Tin-zinc tooj liab. Qhov ntau ntawm cov zinc yog yaj rau hauv cov tooj-tin alloy, thiab tus nqi ntawm cov zinc ntxiv hauv cov wrought tin tooj dag feem ntau tsis ntau tshaj 4%. Zinc tuaj yeem txhim kho qhov fluidity ntawm lub alloy, nqaim crystallization kub ntau, thiab txo qhov rov qab cais.

- - Tin-zinc-txhuas tooj liab. Hmoov txhuas tsis yog qhov tseeb tau yaj hauv lub tooj-tooj liab. Nws tau faib tawm ntawm dendrites li ib-theem, dub suav. Kev faib cov hmoov txhuas hauv lub taub hau tsis yooj yim rau niaj hnub zoo li niaj zaus, feem ntau ntxiv cov roj me me ntawm cov xaim hluav taws xob tuaj yeem txhim kho nws cov khoom faib thiab rov ua kom zoo dua tus qauv. Hmoov txhuas txo cov kev sib txhuam coefficient ntawm tin tooj liab, txhim kho hnav tsis kam thiab kev siv tshuab, tab sis me ntsis txo cov khoom kho tshuab. 3% rau 5% ntawm zinc feem ntau ntxiv rau cov tooj liab-tooj-txhuas hlau txhawm rau txhim kho cov khoom siv kho tshuab. Ntxiv 0.02% ~ 0.1% zirconium lossis 0.02% ~ 0.1% boron, tshwj xeeb tshaj yog ntxiv 0.02% ~ 0.2% lub ntiaj teb tsis tshua muaj lub ntsiab lus tuaj yeem kho cov hmoov txhuas thiab ua kom muaj kev faib tawm zoo, yog li txhawm rau txhim kho tus qauv, casting thiab txhua yam khoom ntawm cov hlau lead- muaj cov tooj daj.

Lub Nruag Ntawm Cov Bronze Tsis Muaj Tin

- - Cov khoom siv txhuas ua xim txhuas muaj cov khoom siv hluav taws xob zoo heev, kev txhim kho corrosion, hnav tsis kam, zoo fluidity, thiab tuaj yeem muab cov hlau nrum tuab.

- - Casting manganese bronze feem ntau ntxiv nrog aluminium, hlau, npib tsib xee thiab lwm yam, uas yog xeb-tiv taus thiab kub-resistant, thiab yog qhov tsim nyog rau ua qhov chaw ua haujlwm ntawm qhov kub siab.

- - Cam khwb cia txhuas tooj dag feem ntau ntxiv nrog cov hlau, manganese, npib tsib xee thiab lwm yam, uas yog tsim rau ua kom muaj lub zog siab thiab corrosion-resistant qhov chaw.

Siv Tshuaj Hauv Tshuaj Thiab Siv Cov Khoom Uas Siv Ntau Nrho Bronze

| Hom | Nom tswv muaj pes tsawg leeg /% | Daim ntawv thov |

|

|

|

|

|

|

|

|

|

|

|

|

Minghe Casting, nyob hauv Dongguan, Tuam Tshoj, muaj tsheb thauj mus los yooj yim. Mas koom rau hauv txoj kev ua thiab ua cov qib tshwj xeeb ntawm tooj liab alloys thiab txhuas alloys. Copper alloy qib muaj xws li aluminium bronze, silicon bronze, aluminium tooj daj, aluminium nickel bronze, tin bronze, manganese tooj dag, tooj liab liab, tooj dag, thiab lwm yam C94400, C95800, C83600, 10-2, 9-2, CuAl5Sn5Zn5, CuAl9, CuAl9Fe, lwm yam thiab lwm yam., nrog rau cov khoom siv rau kev sim kev soj ntsuam tsom iav kom paub meej qhov tseeb ntawm cov tshuaj lom neeg ntawm cov khoom siv. Kev ua cov cuab yeej suav nrog kev ua tiav ntawm cov khoom siv xws li dav dav, tshuab txiav tshuab, CNC, tshuab chaw, thiab lwm yam

Txoj Cai Kev Kawm Txog Minghe Ntawm Bronze Casting

Minghe Casting fabrication kev pabcuam muaj rau ob qho tib si tsim rau kev muaj tiag thiab qis rau siab ntim ntau lawm khiav ntawm koj cov txhuas casting qhov chaw, zinc casting qhov chaw, magnesium casting, titanium casting qhov chaw, stainless hlau casting qhov chaw, tooj casting casting, hlau casting qhov chaw, tooj dag casting qhov chaw thiab ntau yam ntxiv.

Mus Saib Ntau Cov Luam Hauv Qhov Chaw Kawm >>>

Xaiv Qhov Zoo Tshaj Lij Choj Khoom Siv

Tam sim no, peb cov khoom siv tooj dag tau xa tawm mus rau Asmeskas, Canada, Australia, United Kingdom, Lub Tebchaws Yelemees, Fabkis, Sout Africa, thiab ntau lub tebchaws nyob thoob qab ntuj. Peb yog ISO9001-2015 sau npe thiab tseem tau ntawv pov thawj los ntawm SGS.

Peb cov kev cai bronze casting fabrication kev pabcuam muab cov khoom lag luam ruaj khov thiab pheej yig uas ua tau raws li koj cov kev qhia tshwj xeeb rau kev tsheb, kev kho mob, huab cua, hluav taws xob, khoom noj khoom haus, kev tsim kho, kev ruaj ntseg, tubrog nkoj, thiab ntau dua kev lag luam. Cauj xa koj qhov kev nug lossis xa koj cov duab kos kom tau txais nqe lus dawb hauv lub sijhawm luv.Paj rau peb lossis Email kev muag khoom@hmminghe.com los saib yuav ua li cas peb cov neeg, khoom siv thiab cuab yeej tuaj yeem nqa cov khoom lag luam zoo tshaj plaws rau tus nqi zoo tshaj plaws rau koj qhov bronze casting project.

Peb Muab Cov Kev Pab Cuam Uas Tau Xam Pom:

Minghe Casting cov kev pabcuam ua haujlwm nrog xuab zeb casting casting hlau casting 、 peev casting ploj ua npuas ncauj casting, thiab lwm yam.

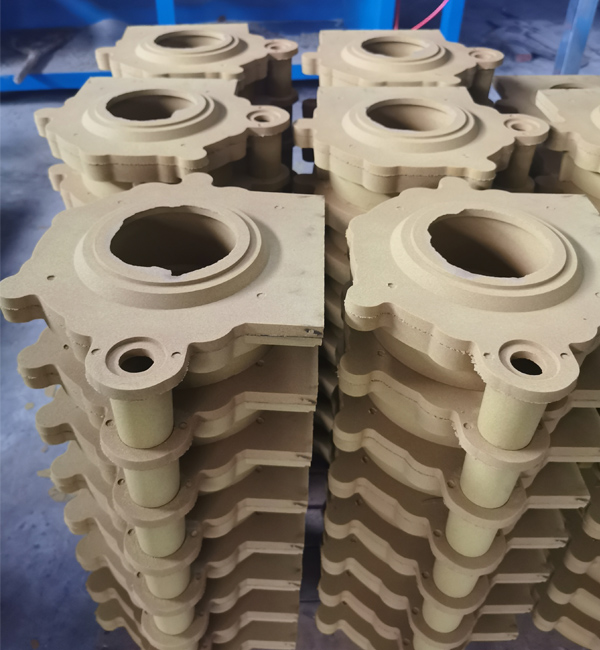

Xuab zeb Casting

Xuab zeb Casting yog cov txheej txheem ib txwm coj ua uas siv cov xuab zeb ua cov qauv ua qauv loj los ua cov pwm. Lub ntiajteb txawj nqus casting feem ntau yog siv rau cov xuab zeb tuaj pwm, thiab lub tshuab nqus dej siab qis, centrifugal casting thiab lwm cov txheej txheem tseem tuaj yeem siv thaum muaj cov kev xav tau tshwj xeeb. Cov txheej txheem xuab zeb muaj ntau yam ntawm kev yoog tau, cov ntawv me me, tej daim loj me, cov khoom yooj yim, cov khoom sib txuam, cov xaj thiab cov khoom loj tuaj yeem siv.

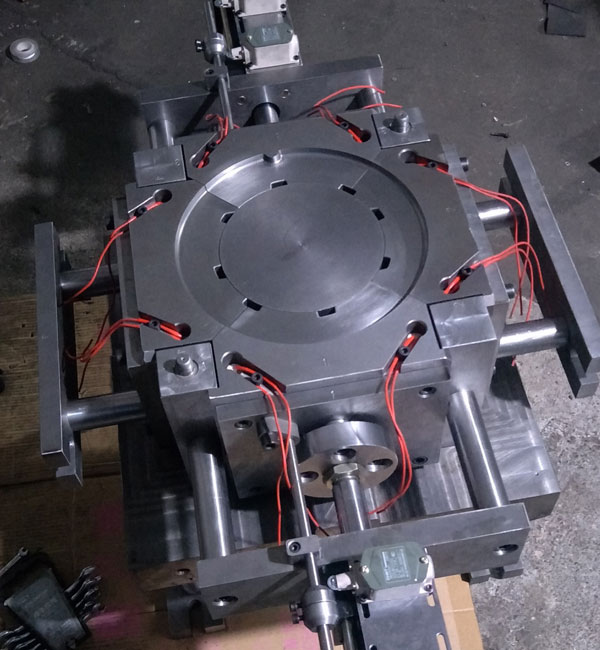

Permanent Mould Casting

Permanent Mould Casting muaj lub neej ntev thiab kev tsim khoom ntau lawm, tsis tsuas yog muaj qhov zoo qhov tseeb thiab qhov chaw du, tab sis kuj muaj lub zog siab dua li cov xuab zeb nrum thiab tsis tshua muaj kev puas tsuaj thaum tib lub hlau nchuav tau nchuav. Yog li no, nyob rau hauv kev lag luam huab hwm coj ntawm nruab nrab thiab me me tsis muaj hlau tsis zoo, ntev li ntev melting kis ntawm cov khoom siv casting tsis siab dhau, cov hlau casting feem ntau nyiam.

Peev Casting

Qhov loj tshaj kom zoo dua peev casting yog tias vim tias cov peev txheej ua lag luam muaj qhov siab dav thiab qhov chaw tiav, lawv tuaj yeem txo qhov kev ua haujlwm machining, tab sis tawm ntawm cov nyiaj machining me me rau ntawm qhov chaw nrog cov kev xav tau ntau dua. Nws tuaj yeem pom tias kev siv peev txheej txheej txheem tuaj yeem txuag ntau lub tshuab cuab yeej tshuab thiab ua haujlwm txiv neej-teev, thiab txuag tau cov ntaub ntawv nyoos hlau ntau.

Poob Ua Npuas Ncauj Casting

Poob ua npuas ncauj casting yog los sib txuas ua ke paraffin siv quav ciab lossis ua npuas ua qauv zoo ib yam li cov casting loj thiab cov duab mus rau hauv pawg pawg. Tom qab txhuam thiab ziab rov qab ua kom tiav txheej, lawv muab faus rau hauv cov xuab zeb quartz qhuav rau kev co qauv, thiab nchuav hauv qab qhov tsis zoo los ua kom cov qauv ua pa. , Lub tshuab ua kua hlau nyob hauv txoj haujlwm ntawm tus qauv thiab tsim qauv txheej txheem txheej tom qab ua kom ruaj khov thiab txias.

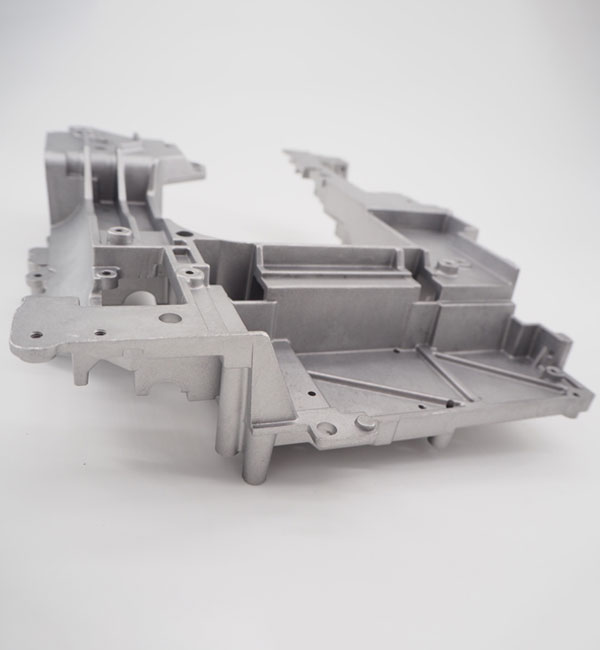

Tuag Casting

Kev tuag casting yog txheej txheem txheej txheem hlau, uas yog tus cwj pwm los ntawm kev thov kev kub siab rau lub tshuab hlau uas siv cov kab noj hniav ntawm cov pwm. Cov pwm feem ntau yog ua los ntawm qib siab-lub zog alloys, thiab cov txheej txheem no me ntsis zoo ib yam li kev txhaj tshuaj molding. Feem ntau cov hlau tuag yog hlau tsis xeb, xws li zinc, tooj, txhuas, magnesium, txhuas, yajthem, thiab txhuas-txhuas alloys thiab lawv cov alloys. Minghe tau ua Tuam Tshoj cov theem saum toj kawg nkaus tuag qhov kev pab cuam txij li thaum 1995.

Centrifugal Casting

Centrifugal Casting yog cov txheej txheem thiab cov txheej txheem ntawm kev txhaj tshuaj kua hlau rau hauv kev hloov pauv pwm siab, kom cov kua hlau ua lub zog yog lub zog centrifugal suab los txhawm rau txhawm rau pwm thiab tsim kev ua haujlwm. Vim los ntawm lub zog centrifugal zog, cov kua hlau ua kua tuaj yeem sau pwm pwm zoo rau hauv cov kev taw qhia radial thiab tsim dawb qhov chaw ntawm txoj haujlwm pov; nws cuam tshuam cov txheej txheem crystallization ntawm cov hlau, thiaj li txhim kho cov neeg kho tshuab thiab lub zog ntawm kev ua haujlwm.

Tsawg Tus Nqi Casting

Tsawg Tus Nqi Casting txhais tau hais tias lub pwm feem ntau tso rau saum cov ntsia ntawm crucible, thiab cov cua nrawm nkag mus rau hauv tus crucible ua rau kom muaj qhov ntsuas qis (0.06 ~ 0.15MPa) nyob rau saum npoo ntawm molten hlau, kom cov hlau molten sawv los ntawm cov yeeb nkab riser rau sau cov pwm thiab kev tswj xyuas Kev qhia ua yeeb yam. Qhov txheej txheem casting no muaj kev pub mis zoo thiab cov qauv ntom, yooj yim rau qhov loj dua-cov phab ntsa nyuaj ua si, tsis muaj tus ris, thiab tus nqi hlau rov qab yog 95%. Tsis muaj kuab paug, yooj yim kom paub cov automation.

Nqus Plua Plav Casting

Nqus Plua Plav Casting yog cov txheej txheem casting nyob rau hauv uas cov hlau yog smelted, nchuav thiab crystallized nyob rau hauv lub tshuab nqus tsev. Lub tshuab nqus tsev ua tau tuaj yeem txo cov roj ntsiab lus hauv cov hlau thiab tiv thaiv hlau hlau. Txoj kev no tuaj yeem tsim ua cov xav tau tshwj xeeb ntawm cov hlau alloy castings thiab tsis yooj yim oxidized titanium alloy castings. Minghe Casting muaj lub tshuab nqus tsev casting sub-hoobkas, uas yog txaus los daws txhua yam teeb meem ntsig txog kev nqus casting