Qhov Ntaus Khoom Kho Mob

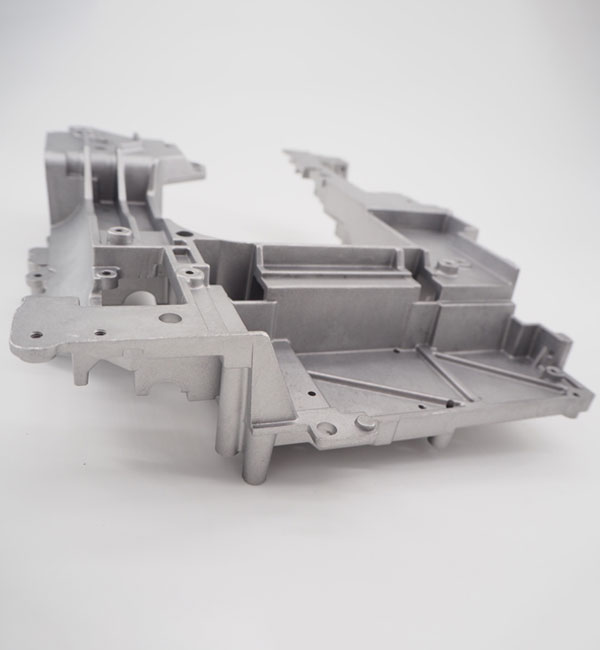

Kev Kho Mob Qhov Chaw Kho Mob Los Ntawm Casting & Cnc Machining

IATF 16949 CERTIFIED CAST RAUG THIAB CNC MACHINING RAU QHOV KEV KHW

Kev lag luam ntaus ntawv kho mob koom nrog ntau yam lag luam xws li tshuaj, tshuab, khoom siv hluav taws xob, thiab plastics. Nws yog ntau txoj kev qhuab qhia, kev txawj ntse, thiab kev siv nyiaj txiag ntau hauv kev lag luam. Cov yam ntxwv tseem ceeb ntawm cov cuab yeej siv kho mob siab yog digitization thiab khoos phis tawj. Nws yog crystallization ntawm ntau qhov kev qhuab qhia thiab hla kev niaj hnub muaj kev kawm siab. Nws cov khoom muaj cov txheej txheem ua haujlwm tau zoo thiab muaj txiaj ntsig siab. Yog li no, lawv yog qhov kev sam xeeb ntawm kev sib tw ntawm kev sib tw loj ntawm cov teb chaws science thiab cov tuam txhab loj thiab cov tuam txhab loj thoob ntiaj teb. Qhov kev tsis pub nkag tau yog siab heev.

Cov cuab yeej siv kho mob xa mus rau cov twj paj nruag, khoom siv, khoom siv, hauv cov tshuaj tiv thaiv kab mob hauv vitro thiab cov ntsuas ntsuas, cov ntaub ntawv thiab lwm yam khoom sib xws lossis cov khoom siv ncaj qha lossis ncaj qha rau tib neeg lub cev, suav nrog cov software tsim nyog.

Cov nqi hluav taws xob feem ntau yog tau los ntawm kev siv lub cev, tsis yog los ntawm pharmacology, kev tiv thaiv kab mob, lossis cov metabolism, lossis txawm hais tias cov hauv kev no koom nrog tab sis tsuas yog ua tus pabcuam. Lub hom phiaj yog kuaj mob, tiv thaiv, saib xyuas, kho lossis txo tus kab mob; kev kuaj mob, kev saib xyuas, kev kho mob, kev thim rov qab lossis kev raug mob ntawm kev raug mob; kev kuaj xyuas, hloov, kho lossis txhawb nqa ntawm cov qauv kev ua haujlwm hauv lub cev lossis ua haujlwm ntawm lub cev; kev pab cuam lub neej lossis kev saib xyuas; tshuaj tiv thaiv cev xeeb tub; Muab cov ntaub ntawv rau kev kho mob lossis kev kuaj mob los ntawm kev kuaj cov qauv ntawm tib neeg lub cev.

Peb qhov chaw kho mob precision tuag casting thiab kev pab cuam machining muaj peb cov neeg ntseeg siab rau cov khoom lawv tau txais. Kev ntseeg siab yog lub sijhawm muaj nuj nqi tshwj xeeb yog tias koj yog tus tsim lossis chaw tsim khoom ntawm cov khoom kho mob. Lub npe Minghe yog lub ntsiab lus hauv kev kho mob. Ua tsaug rau peb lub koob npe nrov ntawm qhov ua tau raws li qhov xav tau tshwj xeeb rau cov khoom siv sib xyaw thiab cov khoom tsis yooj yim, peb xa cov khoom xa tuaj kom ntseeg tau peb cov neeg siv tshuaj kho mob tsis tuaj yeem nyob yam tsis muaj.

Hu rau peb tus kws khomob tsim kho tshuab hnub no los tham txog qhov tshwj xeeb ntawm koj cov phiaj xwm nyuaj.

1.Cov Khoom Siv Kho Mob Kev Lag Luam.

MINGHE cov kev paub tsis muaj txheej txheem hauv kev tsim, kev txhim kho, thiab kev tsim khoom ntawm precision tuag nrum thiab cnc machining cov kev daws teeb meem rau ntau cov kev kho mob, suav nrog tab sis tsis txwv rau:

-

Cov cuab yeej phais mob yooj yim; cov khoom siv neurosurgery; ophthalmic phais cov twj; kho cov cuab yeej kho hniav; cov cuab yeej phais plawv thoracic thiab hlab plawv; phais plab zom mov; twj paj nruag anorectal urinary;

Orthopedics (Orthopedics) phais seev; cov cuab yeej siv phais mob phais plab thiab chaw kho mob; txhaj tshuaj tho; cov khoom siv tshuaj xyuas dav dav; cov cuab yeej kho mob hluav taws xob; cov cuab yeej kho mob kho qhov muag, twj paj nruag thiab cov cuab yeej siv dav dav; cov cuab yeej kho mob kho kom zoo nkauj, twj paj nruag thiab cov cuab yeej siv endoscopes; -

Cov cuab yeej siv kho mob ultrasound thiab cov cuab yeej muaj feem xyuam; cov cuab yeej siv kho mob laser; cov cuab yeej siv kho mob siab; cov khoom siv kho lub cev; tsoos suav tshuaj kho mob; cov khoom siv kho mob sib nqus; cov khoom siv kho mob X-ray; kev kho mob X-ray pab khoom siv thiab cov khoom siv; cov khoom kho mob nkees hluav taws xob;

-

Cov cuab yeej siv kho mob hluav taws xob tiv thaiv thiab khoom siv; kuaj ntsuas tsom ntsuas cov cuab yeej (tsis suav nrog hauv tshuaj tiv thaiv kab mob tshuaj ntsuab); kev kuaj mob thiab cuab yeej siv yooj yim; kev siv cov ntshav ua ntxiv thiab cov khoom siv ua ntshav;

-

Chav khiav hauj lwm, chav kho mob ceev, kev kuaj mob thiab chav kho cov cuab yeej thiab khoom siv hluav taws xob; cov khoom siv kho hniav thiab khoom siv; pawg ntseeg cov khoom siv thiab khoom siv; cov khoom siv tshuaj tua kab mob thiab kom tsis muaj menyuam thiab khoom siv; kev kho mob khaub thuas, tsis kub, cov khoom siv tub yees thiab khoom siv;

2.Vim Vim Li Cas Xaiv Peb Rau Koj Tej Haujlwm Kho Mob

Minghe muaj ntau tshaj li ntawm 30 xyoo ntawm kev paub pab cov kws kho mob tsim qauv tsim khoom muaj txiaj ntsig kev lag luam. Thaum koj koom tes nrog Minghe koj tuaj yeem tau txais txiaj ntsig nram qab no los ntawm peb txoj kev tuag casting:

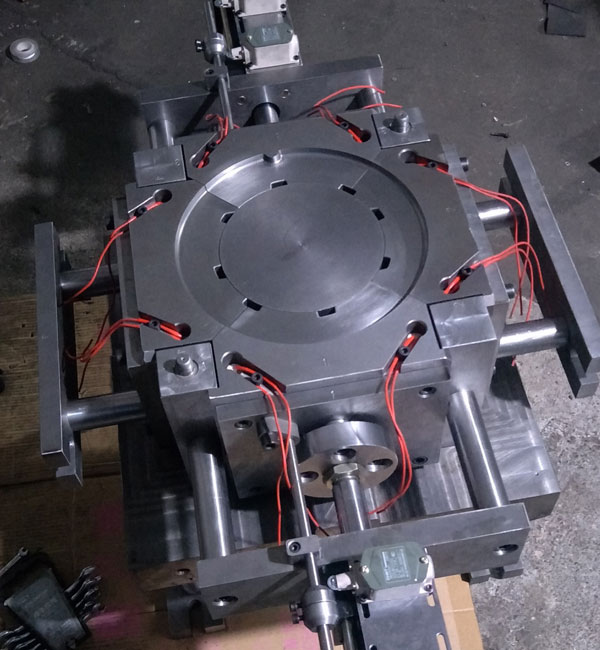

- Minghe tuag casting lag luam nta 40 presses ncua los ntawm 250 txog 3000 tuj. Peb ua raws qee qhov kev xav tau ntawm kev kho mob feem ntau khiav raws qhov ntim, qhov loj me thiab qhov nyuaj. Vim tias peb qhov kev tsim vaj tsev tsim qauv thiab qauv tsim muaj peev xwm, peb paub los ntawm peb cov neeg siv khoom ua cov tuam txhab uas tuaj yeem txo qee qhov kev cov nyom, thiab ua rau kev tsim khoom lag luam kom muaj txiaj ntsig zoo.

- Minghe tuaj yeem pab tso koj cov saw hlau los ntawm kev muab ua tiav pob ntawm kev tuag cov kev pabcuam ntxiv rau kev txhawb nqa kev tsim kho tshuab, pwm tsim thiab kev daws teebmeem, tshuab ua haujlwm, thiab lub logistics.

- Minghe yog ISO tau ntawv pov thawj tuag Casting Chaw tsim tshuaj paus thiab muaj kev paub dhau los ntawm kev tsim qauv thiab tsim khoom siv zinc thiab aluminium qhov chaw mus rau kev kho mob tshwj xeeb.

- Nrog cov nias ntu los ntawm qhov loj mus rau me me, peb muaj lub peev xwm los tsim qhov chaw kho mob ntawm txhua qhov ntau thiab tsawg, los ntawm lub hau npog mus rau cov tsev loj rau cov tsheb thauj khoom.

- Peb yog ITAF 16949 ntawv lees paub thiab tuaj yeem muab cov khoom lag luam rau cov khoom siv rau kev siv tub rog thiab kev kho mob.

- Peb lub thev naus laus zis coj los tsim kho kom zoo thiab kev ua kom muaj zog. Peb cov khoom siv thev naus laus zis suav nrog AutoCAD, Pro-E, MAGMAsoft®, CAD / CAM thiab EDI kev ua haujlwm, thiab FARO Laser Scanning.

3.Txoj Kev Pabcuam Kho Khoom Siv rau Cov Khoom Kho Mob Khoom Siv Kev Cai

Ntxiv rau, Minghe tseem muab CNC machining, peev casting, xuab zeb casting thiab lwm yam kev pab cuam cuam tshuam nrog kev kho mob ntu.

| Cnc Machining Qhov Chaw Kho Mob |

| Peev Casting Cov Kws Kho Mob |

| Xuab Zeb Nrum Kho Cov Khoom Kho Mob |

4. Cov Kev Ntsuas Ntawm Peb Cov Ua Ntej Ua Phaj rau Kev Kho Mob

Ntxiv rau, Minghe tseem muab CNC machining, peev casting, xuab zeb casting thiab lwm yam kev pabcuam cuam tshuam nrog cov chaw kho mob tau kho.

AL360, AL380, AL383, thiab AL413, ZA-8, ZA-12, ZA-27, Txhuas A356,

Dub, Dawb, Nyiaj, Liab, Ntuj, Xiav, Ntsuab thiab xim sib txawv raws li cov neeg siv khoom xav tau

Xuab zeb tua, txhaj tshuaj tua blasting, polishing, anodizing, oxidation, electrophoresis, chromate, hmoov txheej thiab pleev xim

Tuag Casting, Pwm Raug, CNC milling, CNC xa, CNC drilling

Zoo hloov chaw twj tso kua mis / impeller twj tso kua mis / dav hlau twj tso kua mis / ntsug twj tso kua mis / kab rov tav twj tso kua mis / ib qho nqus twj tso kua mis / ob chav nqus dej / lub twj tso kua mis lub cev / lub tshuab nqus cov twj siv roj

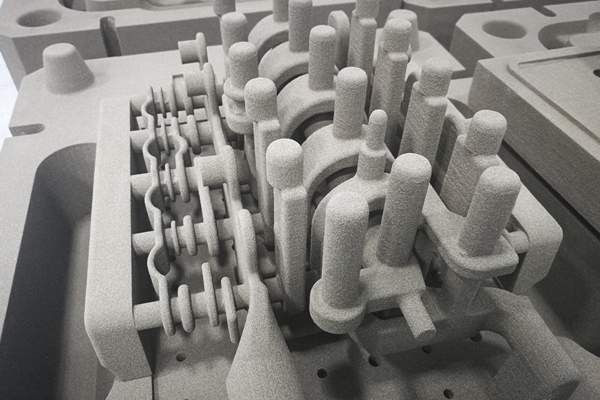

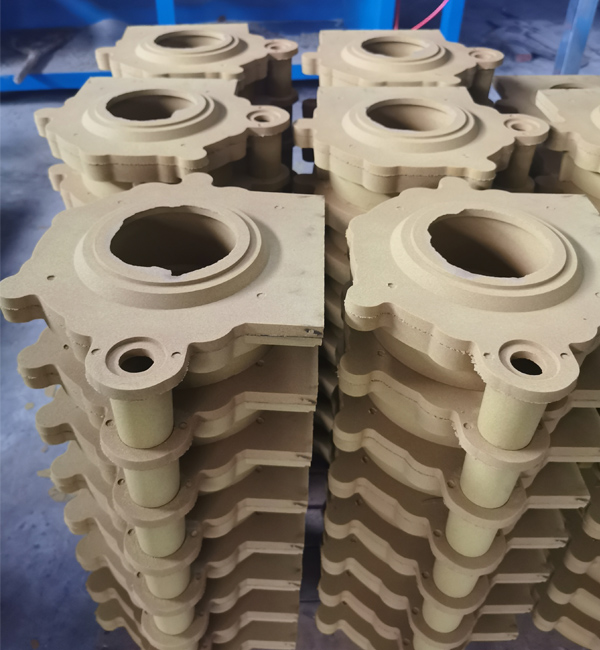

Qhov Kev Tshawb Nrhiav Minghe Case Ntawm Cov Khoom Siv Kho Khoom Siv Casting Qhov Chaw

Koj muaj cov txheej txheem tsim ntawm, Minghe Casting Company tuaj yeem pab koj tig nws mus rau qhov kev muaj tiag. Nrog cov cuab yeej tsim nyog, muaj kev paub txog kev txawj ntse, thiab ua kom pom tseeb ntawm qhov zoo .. Los ntawm cov cuab yeej tsim los ua kom tiav thiab tom qab ntawd rau kev xa khoom, Minghe Casting xyuas kom meej tias txhua qhov project ua tiav rau tus txheej txheem siab thiab tias koj cov xaj tau xa nrog sijhawm, txhua zaus Cov.

Mus Saib Ntau Cov Luam Hauv Qhov Chaw Kawm >>>

Xaiv Qhov Khoom Siv Hluav Taws Xob Zoo Tshaj Plaws Hauv Cov Khoom Siv Casting

Tam sim no, peb cov khoom siv kho mob casting qhov chaw raug xa tawm mus rau Asmeskas, Canada, Australia, United Kingdom, Lub Tebchaws Yelemees, Fabkis, Sout Africa, thiab ntau lub tebchaws nyob thoob qab ntuj. Peb yog ISO9001-2015 sau npe thiab tseem tau ntawv pov thawj los ntawm SGS.

Kev cai Tuam Tshoj tuag casting kev pab muab cov suab paj nruag ruaj khov thiab tsim nyog uas ua tau raws li koj cov kev qhia tshwj xeeb rau kev kho tsheb, kev kho mob, huab cua, khoom siv hluav taws xob, khoom noj khoom haus, kev tsim kho, kev ruaj ntseg, tubrog nkoj, thiab ntau yam kev lag luam. Cauj xa koj qhov kev nug lossis xa koj cov duab kos kom tau txais nqe lus dawb hauv lub sijhawm luv.Paj rau peb lossis Email kev muag khoom@hmminghe.com txhawm rau saib peb cov neeg li cas, cov cuab yeej siv thiab cov cuab yeej tuaj yeem nqa tau qhov zoo tshaj plaws rau tus nqi zoo tshaj plaws rau koj cov khoom kho mob qhov project.

Peb Muab Cov Kev Pab Cuam Uas Tau Xam Pom:

Minghe Casting cov kev pabcuam ua haujlwm nrog xuab zeb casting casting hlau casting 、 peev casting ploj ua npuas ncauj casting, thiab lwm yam.

Xuab zeb Casting

Xuab zeb Casting yog cov txheej txheem ib txwm coj ua uas siv cov xuab zeb ua cov qauv ua qauv loj los ua cov pwm. Lub ntiajteb txawj nqus casting feem ntau yog siv rau cov xuab zeb tuaj pwm, thiab lub tshuab nqus dej siab qis, centrifugal casting thiab lwm cov txheej txheem tseem tuaj yeem siv thaum muaj cov kev xav tau tshwj xeeb. Cov txheej txheem xuab zeb muaj ntau yam ntawm kev yoog tau, cov ntawv me me, tej daim loj me, cov khoom yooj yim, cov khoom sib txuam, cov xaj thiab cov khoom loj tuaj yeem siv.

Permanent Mould Casting

Permanent Mould Casting muaj lub neej ntev thiab kev tsim khoom ntau lawm, tsis tsuas yog muaj qhov zoo qhov tseeb thiab qhov chaw du, tab sis kuj muaj lub zog siab dua li cov xuab zeb nrum thiab tsis tshua muaj kev puas tsuaj thaum tib lub hlau nchuav tau nchuav. Yog li no, nyob rau hauv kev lag luam huab hwm coj ntawm nruab nrab thiab me me tsis muaj hlau tsis zoo, ntev li ntev melting kis ntawm cov khoom siv casting tsis siab dhau, cov hlau casting feem ntau nyiam.

Peev Casting

Qhov loj tshaj kom zoo dua peev casting yog tias vim tias cov peev txheej ua lag luam muaj qhov siab dav thiab qhov chaw tiav, lawv tuaj yeem txo qhov kev ua haujlwm machining, tab sis tawm ntawm cov nyiaj machining me me rau ntawm qhov chaw nrog cov kev xav tau ntau dua. Nws tuaj yeem pom tias kev siv peev txheej txheej txheem tuaj yeem txuag ntau lub tshuab cuab yeej tshuab thiab ua haujlwm txiv neej-teev, thiab txuag tau cov ntaub ntawv nyoos hlau ntau.

Poob Ua Npuas Ncauj Casting

Poob ua npuas ncauj casting yog los sib txuas ua ke paraffin siv quav ciab lossis ua npuas ua qauv zoo ib yam li cov casting loj thiab cov duab mus rau hauv pawg pawg. Tom qab txhuam thiab ziab rov qab ua kom tiav txheej, lawv muab faus rau hauv cov xuab zeb quartz qhuav rau kev co qauv, thiab nchuav hauv qab qhov tsis zoo los ua kom cov qauv ua pa. , Lub tshuab ua kua hlau nyob hauv txoj haujlwm ntawm tus qauv thiab tsim qauv txheej txheem txheej tom qab ua kom ruaj khov thiab txias.

Tuag Casting

Kev tuag casting yog txheej txheem txheej txheem hlau, uas yog tus cwj pwm los ntawm kev thov kev kub siab rau lub tshuab hlau uas siv cov kab noj hniav ntawm cov pwm. Cov pwm feem ntau yog ua los ntawm qib siab-lub zog alloys, thiab cov txheej txheem no me ntsis zoo ib yam li kev txhaj tshuaj molding. Feem ntau cov hlau tuag yog hlau tsis xeb, xws li zinc, tooj, txhuas, magnesium, txhuas, yajthem, thiab txhuas-txhuas alloys thiab lawv cov alloys. Minghe tau ua Tuam Tshoj cov theem saum toj kawg nkaus tuag qhov kev pab cuam txij li thaum 1995.

Centrifugal Casting

Centrifugal Casting yog cov txheej txheem thiab cov txheej txheem ntawm kev txhaj tshuaj kua hlau rau hauv kev hloov pauv pwm siab, kom cov kua hlau ua lub zog yog lub zog centrifugal suab los txhawm rau txhawm rau pwm thiab tsim kev ua haujlwm. Vim los ntawm lub zog centrifugal zog, cov kua hlau ua kua tuaj yeem sau pwm pwm zoo rau hauv cov kev taw qhia radial thiab tsim dawb qhov chaw ntawm txoj haujlwm pov; nws cuam tshuam cov txheej txheem crystallization ntawm cov hlau, thiaj li txhim kho cov neeg kho tshuab thiab lub zog ntawm kev ua haujlwm.

Tsawg Tus Nqi Casting

Tsawg Tus Nqi Casting txhais tau hais tias lub pwm feem ntau tso rau saum cov ntsia ntawm crucible, thiab cov cua nrawm nkag mus rau hauv tus crucible ua rau kom muaj qhov ntsuas qis (0.06 ~ 0.15MPa) nyob rau saum npoo ntawm molten hlau, kom cov hlau molten sawv los ntawm cov yeeb nkab riser rau sau cov pwm thiab kev tswj xyuas Kev qhia ua yeeb yam. Qhov txheej txheem casting no muaj kev pub mis zoo thiab cov qauv ntom, yooj yim rau qhov loj dua-cov phab ntsa nyuaj ua si, tsis muaj tus ris, thiab tus nqi hlau rov qab yog 95%. Tsis muaj kuab paug, yooj yim kom paub cov automation.