Pwm Raug

Xav tau pwm ua cov khoom siv rau cov khoom loj ntawm ntau qhov chaw tsim khoom? Nrhiav tus nqi zoo dua thiab siv sij hawm ntev ntawm txoj kev tsim khoom? Tsis txhob qhaj peb tuag tuag casting thiab pwm kev pabcuam tsim khoom! Ntawm Minghe, peb muab cov khoom lag luam zoo thiab pheej yig tuag nrum rau cov qauv thiab ntau lawm seem nrog cov sijhawm hloov ceev.

Dab Tsi Yog Tuag Casting Pwm Raug?

Cov ntaub ntawv tuag-tshuab, tuag-tshuab ua pwm, thiab pwm kev lag luam yog peb yam tseem ceeb ntawm kev tuag-casting ntau lawm, thiab tsis muaj leej twg uas tsis tseem ceeb. Cov txheej txheem tuag-ua cov txheej txheem yog cov organic thiab kev siv tag nrho ntawm peb yam, kom nws tuaj yeem ruaj khov, zoo nkauj thiab muaj txiaj ntsig tsim cov yeeb yam tsim nyog nrog cov yam ntxwv zoo, sab hauv, thiab qhov ntev uas ua tau raws li cov cai ntawm kev kos duab lossis kev pom zoo, los yog txawm tias qhov zoo castings. ;

Tuag-casting pwm yog ib qho khoom siv rau nrum hlau ntu, qhov khoom siv rau kev ua kom tuag-casting txheej txheem ntawm kev mob siab tuag-casting tuag forging tshuab. Cov txheej txheem txheej txheem ntawm qhov tuag-casting yog: thawj zaug kev nrawm lossis siab nrawm ntawm cov hlau ua tiav rau hauv cov kab noj hniav ntawm cov pwm, cov pwm muaj qhov kab noj hniav txav ntawm qhov chaw, nws yog pressurized forging nrog cov txheej txheem txias ntawm molten hlau, uas tshem tawm qhov shrinkage ntawm seem. Cov xoob xoob tsis zoo kuj ua rau cov qauv sab hauv ntawm qhov khoob tsis tau tawg kom tawg cov nplej hauv lub xeev forged. Cov cuab yeej siv tag nrho ntawm qhov khoob tau hloov kho ntau yam.

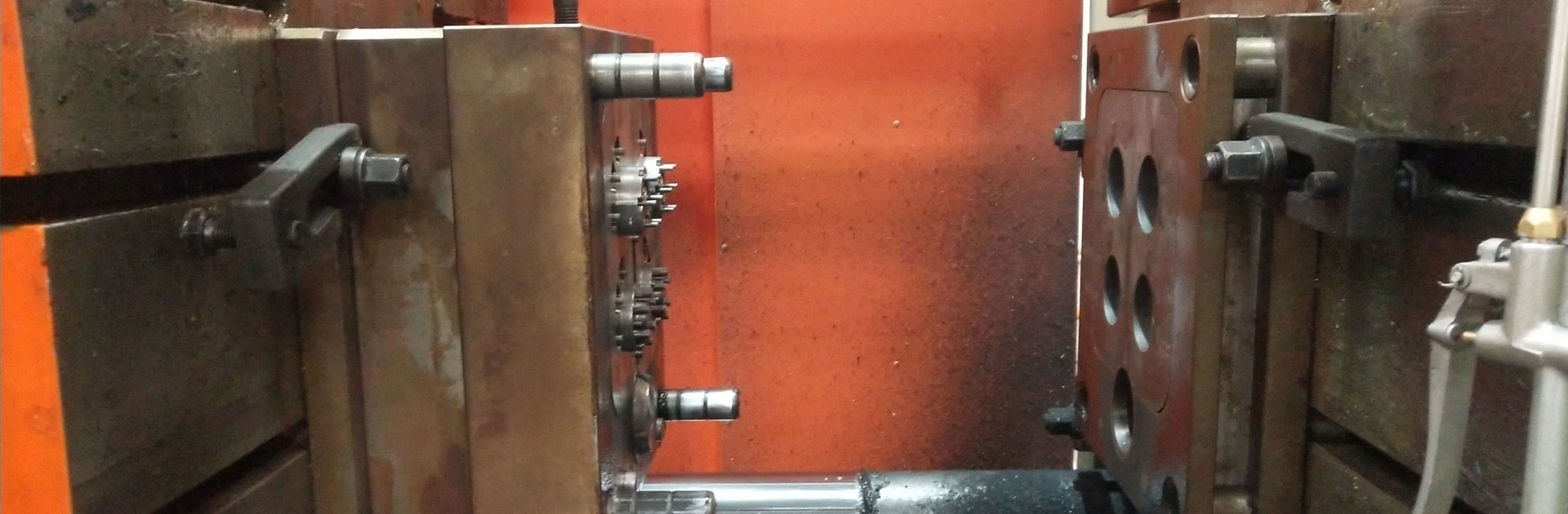

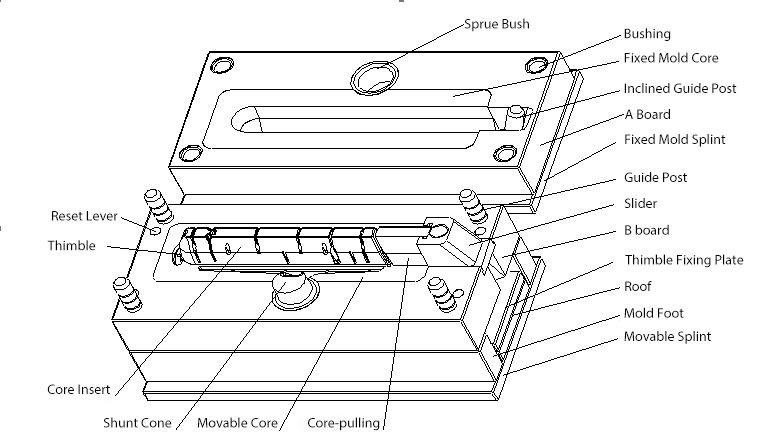

Kev Sib Sau Ua Cov Tuag Casting Mould

- Moulding ib feem (tsiv thiab tsau pwm tub ntxhais, molding tso nrog, tub ntxhais rub tawm, thiab lwm yam)

- Pwm puag feem (tsiv thiab tsau pwm splint, AB pawg thawj coj saib, pallet, pwm taw)

- Bypass system (lub tes tsho qe, lub khob hliav qab, hla khiav, sab hauv thiab lub qhov hluav taws xob)

- Dej dhau system (tso roj tank, tso dej kom puv)

- Ejection mechanism (thimble, thimble kho phaj, ejection phaj, rov qab qib)

- Cov seem txheej txheem (phau ntawv qhia tom qab, phau ntawv qhia lub tes tsho, theem nrab phau ntawv qhia, tes tsho nruab nrab)

- Cov tub ntxhais-rub tawm tshuab (cov tub ntxhais-rub tawm, tawm taw qhia ncej, clamping thaiv, caij nplooj ntoos hlav, thiab lwm yam)

- Lwm tus (lub kaw lus txias, cua sov, tsim kom muaj kem, thiab lwm yam)

Cov tuag tuag casting pwm cov khoom lag luam

H13 (tshav kub-resistant hlau) rau pem hauv ntej thiab nram qab pwm cores, tub ntxhais rub cores, txhav tes tsho, shunt cones, thiab lwm yam); 45 # steel (rau A, B phaj, sliders, inclined phau ntawv qhia ncej, thiab lwm yam); T8, T10 (phau ntawv qhia ncej), Qhia lub tes tsho, thimble, rov qab qws, thiab lwm yam); A3 hlau (pem hauv ntej thiab nram qab pwm splints, pallets, thimble daim hlau, pwm taw, thiab lwm yam)

Cov Txheej Txheem Txheej Txheem Kev Tuag Casting Pwm

- Raws li cov ntaub ntawv siv hauv cov khoom lag luam, cov duab thiab qhov raug ntawm cov khoom thiab lwm yam ntsuas, cov txheej txheem raug tshuaj xyuas thiab cov txheej txheem raug txiav txim siab.

- Txheeb xyuas qhov chaw ntawm cov khoom hauv cov pwm kab noj hniav, txheeb xyuas thiab tsim cov seem ntawm qhov chaw, cov kab ke ua haujlwm thiab cov txheej txheem ntim.

- Tsim qhov sib dhos tseem ceeb thiab kho cov hau kev ntawm txhua qhov haujlwm.

- Tsim ntawm tub ntxhais rub deb nrug thiab yuam.

- Tsim ntawm ejector mechanism.

- Kev txiav txim siab tuag lub tshuab tuag, tsim cov pwm puag thiab cov khoom siv txias.

- Txheeb xyuas qhov sib txheeb ntev ntawm lub pwm thiab tuag-casting tshuab, thiab kos cov txheej txheem kos duab ntawm cov pwm thiab txhua ntu.

- Tus qauv tsim tiav

Qhov zoo ntawm kev tuag casting pwm kev lag luam thiab kev pab cuam moulding

- Qhov loj me ntawm qhov tseeb.

- Cov khoom lag luam siab, yooj yim kom paub lub lag luam tsis siv neeg.

- Zoo tshaj plaws nto tiav.

- Loj ntim ntau lawm muaj.

- me me xav kom tiav ntu qhov chaw tom qab molding.

- Automation txuag cov nqi tsim khoom.

- Zoo kawg thiab rov ua dua thiab yooj.

- Tuag Casting ua rau cov khoom seem qis uas piv rau cov txheej txheem tsim ua ib txwm muaj xws li CNC machining.

- Txo cov khoom pov tseg tsawg kawg.

Kev Tsim & Pwm Ua Service Online - Zoo Tshaj Tuag Casting Mould Chaw Tsim Tshuaj Tuam Txhab Hauv Suav

Minghe Casting yog ib qho zoo tshaj plaws pwm tsim nyob rau hauv Suav teb, muab cov pwm tsim kev daws teeb meem rau txhua qhov kev lag luam, suav nrog kev coj teeb pom kev zoo, cooker, tsheb tuag casting thiab lwm yam. Peb cov kev pabcuam tseem ceeb muaj xws li nyias ntsa lossis ntau dua tuag casting pwm tsim, tuag casting & peev casting, xuab zeb casting, zoo li hauv CNC machining. Nrog ntau tshaj li ntawm 35 xyoo ntawm kev paub, peb muaj peev xwm los tsim cov kev cai pheej yig txhuas tuag casting qhov chaw, zinc tuag casting qhov chaw thiab qhov chaw magnesium raws li cov neeg siv khoom tshwj xeeb, kos duab lossis kuaj. Peb nyias muaj nyias cov tswv yim txuj ci siab, cov neeg ua haujlwm siab tshaj lij uas ntiav cov cuab yeej zoo tshaj thiab siab ua lub siab tuag cov txheej txheem los xyuas kom meej tias cov pwm ntawm cov khoom ntawm cov nqi pheej yig thiab zoo tshaj plaws. Txawm hais tias koj xav tau cov cuab yeej nrawm nrawm, huab hwm coj ntau lawm ua nrog ua kom nruj, peb pab neeg ntawm cov kws tshaj lij tuaj yeem muab cov tshuaj muaj txiaj ntsig zoo nyob rau txhua theem. Hu rau peb pab kws tshaj lij thiab tau txais tus nqi rau koj qhov cuab yeej pabcuam / kev tsim pwm tsim, peb yuav cim koj lub sijhawm tuag thiab pwm tsim nqi hauv 24 teev!

Vim li cas Xaiv Peb Lub Tuav Pov Tseg Vim Pwm Raug Cov Pwm?

Muaj ntau ntau ntawm cov pwm ua cov tuam txhab. Vim li cas koj yuav tsum xaiv peb ua koj lub cuab tam & tuag casting tsum? Ntawm no yog cov laj thawj:

- Muaj peev xwm ntau lawm thiab kev sis tw nqi rau tuag casting muab kev pab.

- Peb muaj kev nplua nuj tuag nrum pwm tsim kev lag luam rau ntau dua 35 xyoos thiab tau txais lub koob npe zoo.

- Pab tshwj xeeb cov qhua tuaj noj mov thiab kev sib txuas lus.

- Ntau yam ntawm kev tuag casting pwm tsim & hom - nyias ntsa, Txiaj Ntsig Casting, Peev casting & nrum casting yog muaj los ua kom tau raws li kev cai xav tau.

- Ua precision tuag casting qhov chaw raug raws li koj cov duab kos lossis cov qauv.

- Ua kom tiav cov ntu nrog kev ua cov pwm ua kom tiav nyob rau lub sijhawm kom muaj kev txhawb nqa zoo tshaj plaws rau koj R & D tej dej num.

- Peb txoj kev siv tshuab xaim ib txwm, kev tshuaj xyuas kev tsim, thiab kev tsim khoom tso cai rau peb xa cov kev txhaj tshuaj moulding kev txiav txim siab hauv nrawm li 1 hnub.

- Peb tau ua cov cuab yeej tsim khoom siab thiab chaw tsim khoom, tshuab thiab khoom siv los ua qhov tshwj xeeb tshaj plaws tuag casting pwm zoo li kev pom zoo.

- Peb muaj cov kws tshaj lij cov kws txawj thiab cov cuab yeej sib koom tes uas yuav ua qhov sib txawv hauv koj cov sij hawm txhuas, cov nqi thiab qhov kawg zoo.

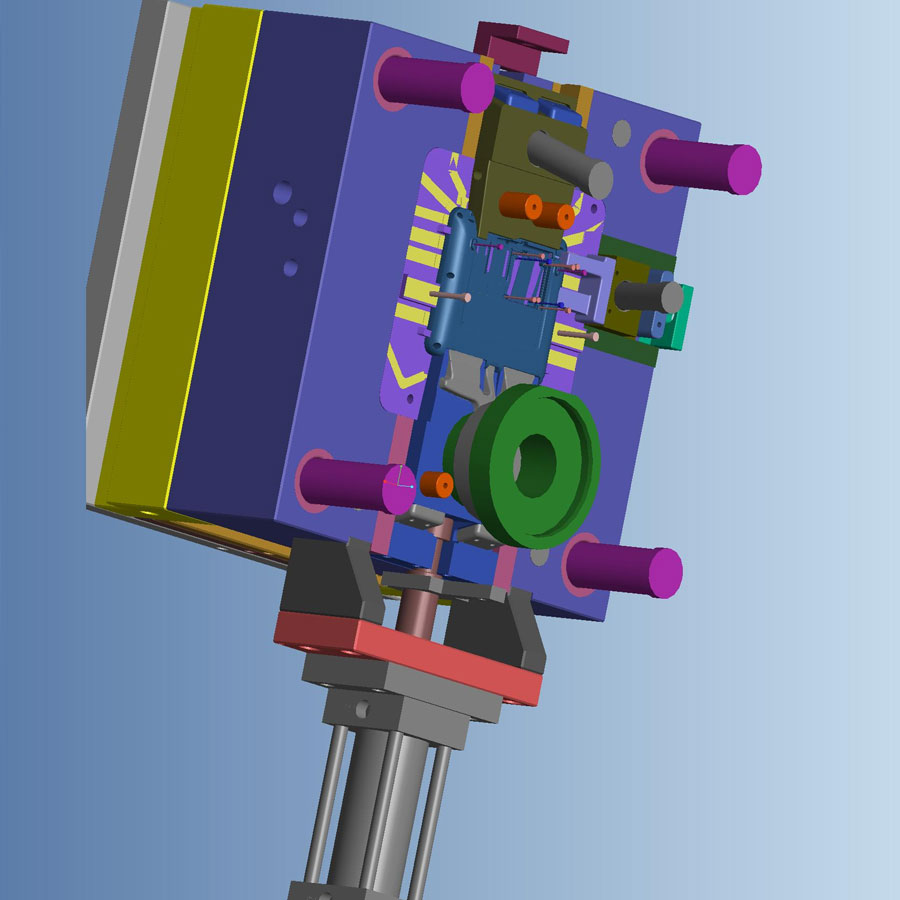

Tuag Casting Mould Tsim & Ua - Ua Li Cas Ua Rau Tuag Casting Mould

Muaj ntau ntau yam yuav tau txiav txim siab rau Tuag Casting, tab sis ib feem tsim rau Die Die Mould yog qhov tseem ceeb heev. Tau txais nws txoj cai tuaj yeem txhais tau qis dua tus nqi nkag, khoom lag luam siab, lub sijhawm ua haujlwm luv, thiab lub rooj sib tham ceev. Ua ib lub hauv paus ntawm kev paub txog cov engineers thiab cov khoom tsim qauv, peb muaj ib tus neeg lossis pab pawg tshaj lij uas tuaj yeem pab koj tsim kev tuag casting pwm qhov chaw ntawm kos. Peb pab pawg ntawm kev tuag casting pwm tsim engineers tsim tshwj xeeb hauv kev kos duab nrog CAD, CAE, CAM, feem ntau siv SOLIDWORKS, PRO ENGINEER, UNIGRAPHICS, thiab MOLD FLOW tsom xam software.

Ntiaj Teb Tuag Casting Pwm Raug Cov Kev Pab

Minghe Casting yog lub chaw tsim khoom lag luam thoob plaws ntiaj teb ntawm ob qho tib si sib xyaw thiab ntau swb swb nrum precision xyaw. Peb cov kws tshaj lij muab cov qauv kev daws teeb meem rau ntau yam kev lag luam suav nrog cov neeg siv khoom siv hluav taws xob, tsheb, kev kho mob, thiab lwm yam. Thaum peb cov engineers tau koom tes ua ntej hauv txoj haujlwm, lawv tuaj yeem pab tsim cov cuab yeej thiab ib feem tshwj xeeb rau hauv kev tsim khoom ntau. Txhua tus ntawm peb cov neeg tau txais kev pom thiab kev txawj ntse thoob plaws txhua theem ntawm txoj haujlwm. Hu rau peb pab pawg engineering kom thov nqe lus hnub no.

Xya Cov Txheej Txheem ntawm Tuag Casting Ua :

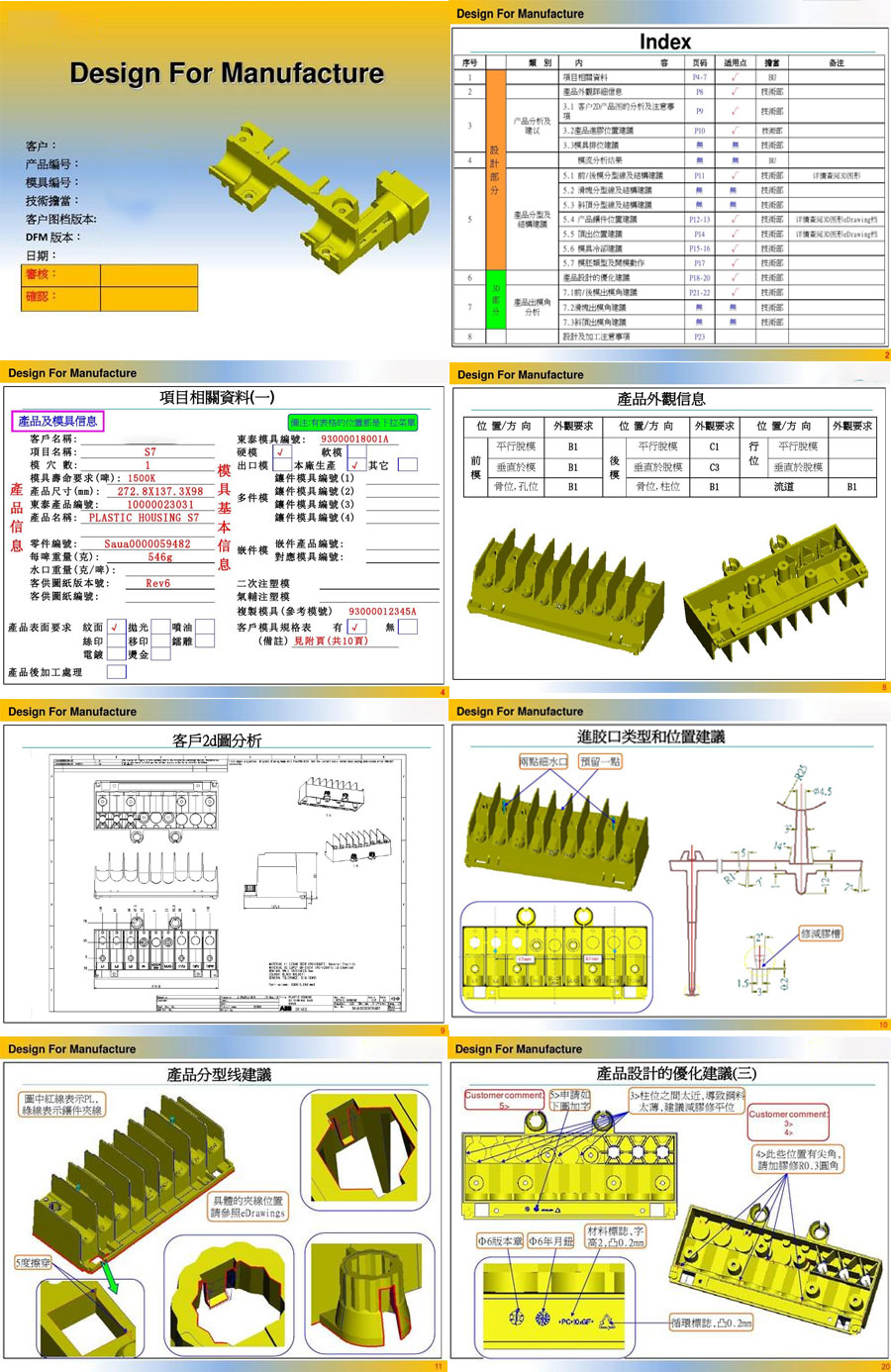

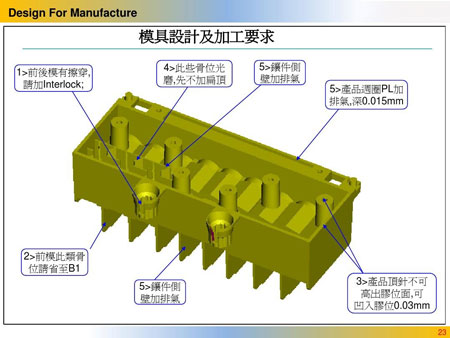

- Kauj Ruam 1: Khoom Muag DFM & Mould Tsim

- Kauj Ruam 2: Mould Steel thiab Lwm Yam Khoom Siv Khoom Txhim Kho

- Kauj Ruam 3: CNC Machining

- Kauj Ruam 4: Kev Kho Cua Sov

- Kauj Ruam 5: HlauCutting / EDM / Milling / Drilling /

- Kauj Ruam 6: Kev Ntsuas Pwm, Kev Sib Daws, thiab Kev Sim

- Kauj Ruam 7: Ua kom zoo nkauj, txhuam, thiab Kev ntxhib los mos

Yog tias cov khoom lag luam kawg tau ua tiav raws li peb qhov kev pom tseeb, nws yog lub sijhawm los txhuam thiab kev ntxhib los mos ua pwm. Tom qab ntawd tag nrho cov txheej txheem xee npe tawm.

Tsim Rau Cov Khoom Siv Hauv Tsev

Multi-slide & Conventional Die Casting: Ntawm Minghe Casting, peb muab ob yam cuab yeej sib txawv: ntau yam swb thiab sib dhos. Txhua tus nyias muaj nyias qhov txiaj ntsig tshwj xeeb thiab peb cov kws tshaj lij muaj peev xwm tuaj yeem txiav txim siab qhov cuab yeej twg yog qhov zoo tshaj plaws rau txhua qhov haujlwm.

- Puas muaj txoj hauv kev nyuaj ntawm cov qauv ntawm cov khoom, txawm hais tias nws xav tau los kho lossis hloov yooj yim; seb txoj haujlwm undercut puas tuaj yeem raug tshem tawm.

- Kev txiav txim siab ntawm cov duab thiab chaw kam rau ua thiab pwm tsim. Yog tias muaj cov duab tsis haum rau lub caij, sim ua kom lawv nyob ntawm tib lub pwm, xws li pwm sab pem hauv ntej lossis pwm sab nraub qaum lossis qhov kawg ntawm kab.

- Tshaj tawm ntawm cov khoom cua ntsawj ntshab lub kaum ntse ntse thiab R lub kaum ntse ntse.

- Txawm hais tias muaj txheej txheem tawv-phab ntsa lossis nyuaj rau daim ntawv ntawm cov khoom, cov khoom lag luam tsim xav tau kev txhim kho.

- Txawm hais tias muaj kev pheej hmoo ntawm lub qhov tawg nyob rau hauv tus qauv nyias ntawm lub qhov chaw thiab seb nws xav tau ntxiv.

- Txawm hais tias cov khoom lag luam yooj yim kom yaig, txawm hais tias nws txias lossis qhov zoo rau kev kho cov qauv khoom.

- Seb cov khoom lag luam tuaj yeem tsim nrog cov khoom siv txo qis rau cov nqi khoom.

- Puas yuav zam cov khoom puas ua tiav kev xaib? Puas yog qhov chaw machining nce nyiaj machining pub thiab cov txheej txheem kev cuab yeej?

- Seb cov khoom lag luam xav tau nce txheej txheem txheej txheem ntawm kev kho saum npoo.

- Yog tias tom qab ua tiav yuav tsum tau stamping, seb puas muaj stamping tuag txoj hauj lwm taw tes.

- Txawm hais tias thaj chaw ua haujlwm ntawm cov khoom lag luam tuaj yeem yooj yim, nws yog ncaj qha los ntawm cov pwm, xws li: lub kaum qhov kom tsis txhob muaj lub qhov loj me, lub tshuab loj loj txiav tsis tuaj yeem ua rau lub ces kaum.

- Seb cov kua nplaum noj txoj hauj lwm thiab cov nozzle kev tshem tawm txoj kev ntawm cov khoom yog tsim nyog, seb puas muaj kev pheej hmoo ntawm chipping, thiab seb nws yooj yim tshem tawm.

- Seb tus qauv tsim ntawm lub hnab slag yog qhov tsim nyog thiab seb nws yooj yim rau kev sib tsoo thiab polishing.

- Cov pwm puag ntawm cov khoom, cov txheej txheem qeb ntawm cov khoom thiab xaiv ntawm cov tonnage ntawm lub tshuab tuag-casting.

- Seb cov khoom puas muaj hnub tim tus lej thiab kab noj hniav tsawg.

- Seb qhov chaw ntawm cov khoom thimble yog tsim nyog, seb nws yuav cuam tshuam rau cov tsos ntawm cov khoom, xws li thimble qhab, pob saum toj kawg nkaus.

- Seb tus qauv tsim ntawm txoj kab ntawm txoj kab tshooj ua haujlwm yog qhov tsim nyog thiab seb nws yooj yim rau txheej txheem thiab tshem tawm.

- Seb qhov chaw tsis muaj zog ntawm cov khoom yuav tsum tau ua kom muaj zog, xws li ntxiv tus choj thiab tshem lawv tom qab ua.

- Yog tias qhov yuav tsum ua siab ntev dhau, yuav tsum muaj kev kuaj mob rau cov neeg siv khoom kom lawv ua siab ntev zam rau lawv.

Txawm hais tias koj tsuas xav tau cov khoom tsim qauv kos duab 、 Pwm Tsim los yog kawg tuag casting qhov nrog cov qhia kiag li, Minghe Die Casting Lub Tuam Txhab tuaj yeem txaus siab koj xav tau nrog cov nqi sib tw, zoo heev thiab cov kev pabcuam zoo tshaj plaws rau cov neeg siv khoom.

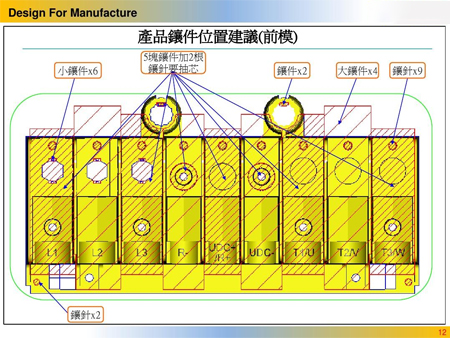

Cov Lus Qhia Ntaus Khoom Siv Cov Lus Pom Zoo

Cov Lus Qhia Ntaus Khoom Siv Cov Lus Pom Zoo

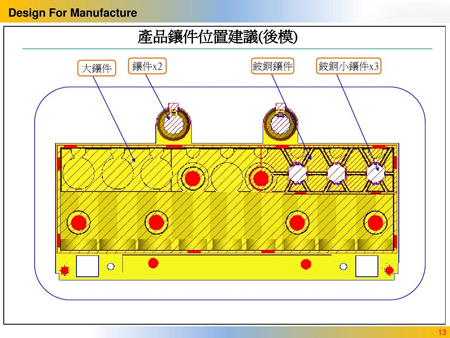

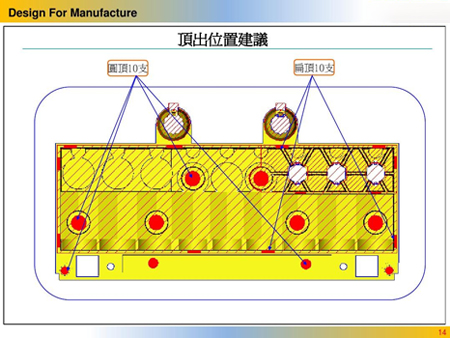

Cov Lus Pom Zoo Kom Ua Cov Haujlwm

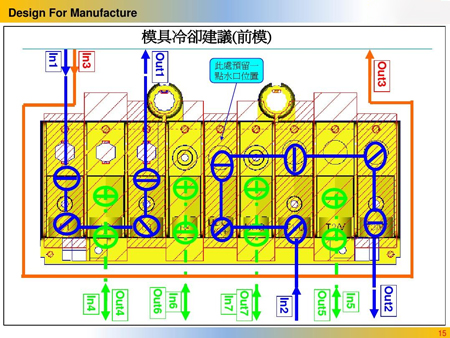

Kev Pom Zoo Pwm Cua Txias (Pem Hauv Pwm)

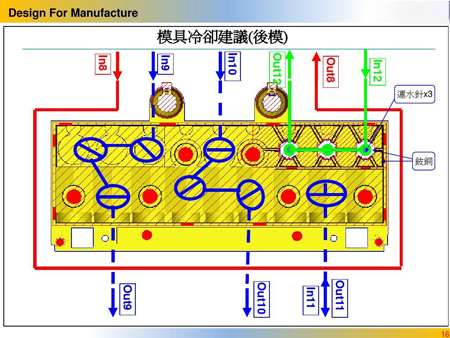

Kev Pom Zoo Pwm Cua Txias (Tom Qab Pwm)

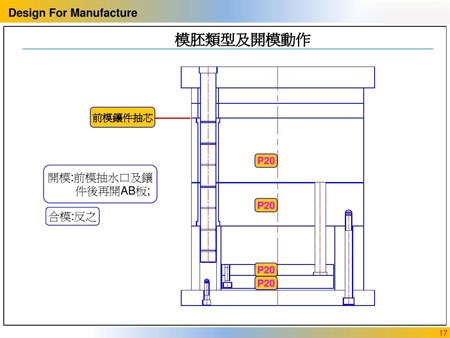

Pwm Hom Thiab Pwm Qhib Kev Ua

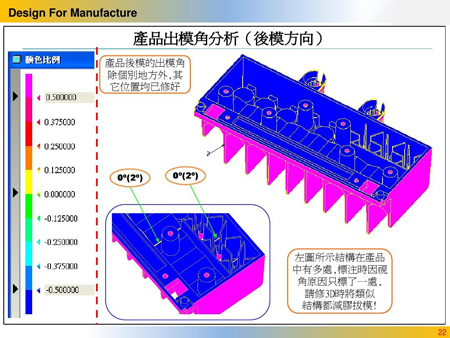

Kev Tshawb Xyuas Cov Pwm Lub Cev (Lub Tsheb Tuaj Cov Ncauj Qha)

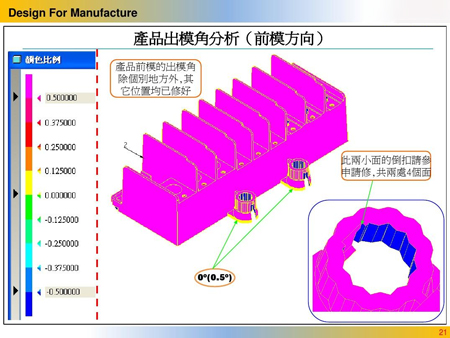

Khoom Siv Lub Pwm Lub Tsho Txheeb Xyuas (Lub Pwm pem hauv ntej)

Pwm Tsim Thiab Machining Yuav Tsum Tau Ua