Drilling

Dab tsi yog Cnc Drilling Txheej & Drilling Machining & - Drilling Cov Kev Pab

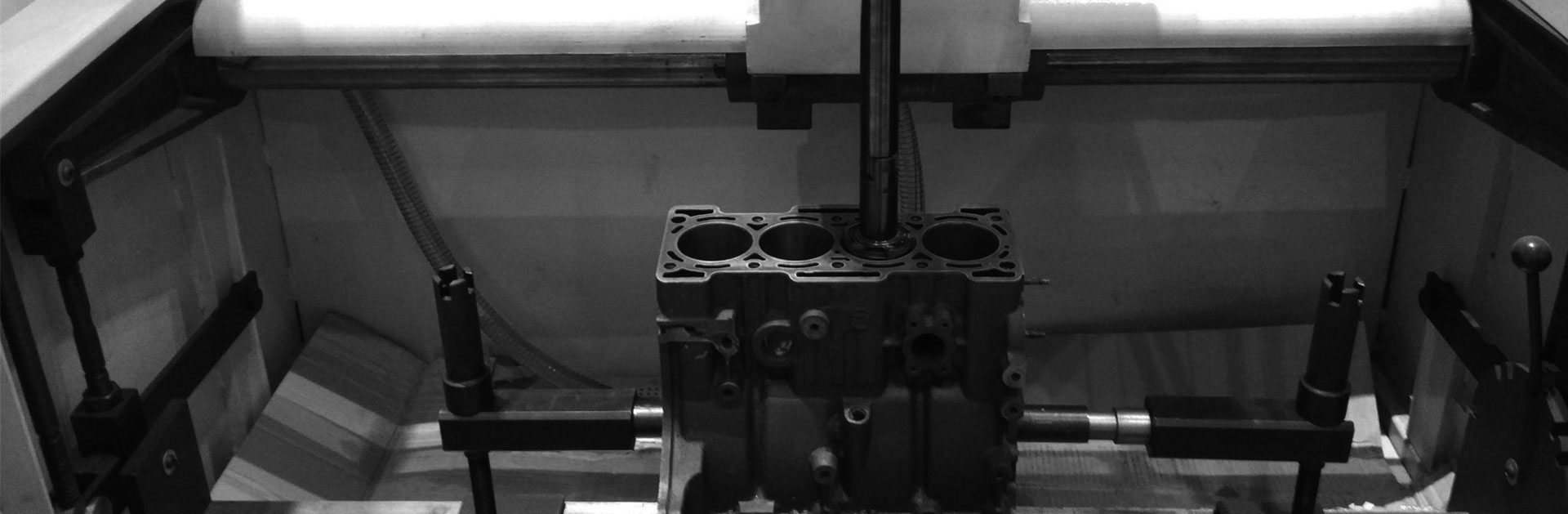

Txhua yam ntawm lub tshuab tsis tuaj yeem ua yam tsis muaj qhov. Txhawm rau txuas cov ntu, ntau cov ntsia hlau txuas, qhov txuas lossis lub qhov rivet ntawm qhov ntau thiab tsawg yuav tsum muaj; yuav kom kho qhov chaw kis tau tus mob, ntau qhov txuas ntawm lub qhov yuav tsum; lub tshuab ntu lawv tus kheej tseem muaj ntau lub qhov (xws li roj qhov, Cov txheej txheem lub qhov, qhov hnyav txo qhov, thiab lwm yam). Kev ua haujlwm ntawm kev siv lub tshuab los ua lub qhov kom ua rau lub qhov yog hu ua lub qhov machining.

Lub puab qhov ntawm sab hauv yog ib qho ntawm cov chaw tseem ceeb uas ua rau cov tshuab kho tshuab. Hauv cov khoom siv tshuab, cov khoom siv nrog qhov feem ntau suav 50% txog 80% ntawm tag nrho cov naj npawb ntawm feem. Cov hom ntawm cov qhov yog tseem muaj ntau yam, suav nrog lub qhov taub, qhov taub conical, lub qhov taub thiab lub qhov taub.

Cov kab cylindrical qhov txawv ntawm qhov dav dav thiab qhov muaj qhov sib sib zog nqus, thiab cov qhov tob yog qhov nyuaj rau tshuab.

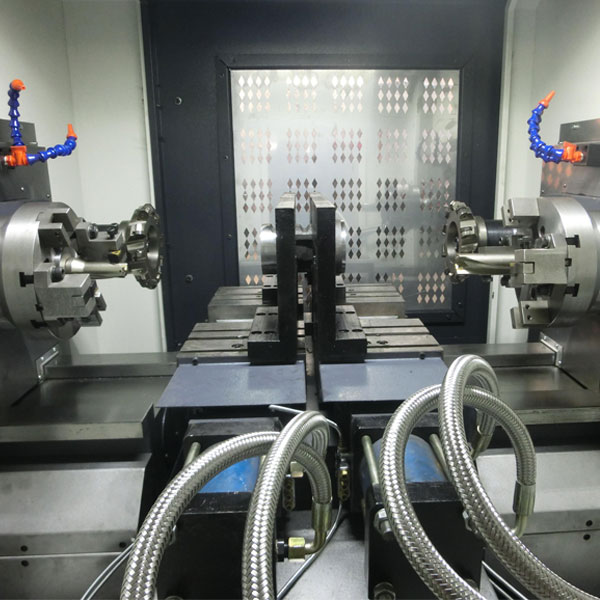

Minghe lub tshuab machining cov kev pab tau pib ntxiv rau kev qhuas thiab txhawb peb txoj kev ua peev xwm. Niaj hnub no, cov neeg siv khoom siv peb cov kev lag luam kev lag luam drilling txawm tias thaum tsim tsis xav tau. Tau 35 xyoo, peb tau hloov kho peb cov kev pabcuam drilling kom muab cov neeg siv khoom lag luam zoo rau lawv cov kev thov tshwj xeeb. Minghe engineers yuav soj ntsuam cov khoom lag luam tshwj xeeb, cov khoom hu tawm sab nraud thiab qhov yuav tsum tau ntim kom xaiv cov tshuaj siv zoo tshaj plaws rau koj qhov project drilling.

Cov Cuab Yeej Siv Kom Ua Tau Rau Qhov Drilling

Hauv cov txheej txheem ntawm lub qhov, nws yog ib qho tsim nyog kom tsis txhob muaj teeb meem xws li lub qhov loj dhau ntawm lub taub loj qhov nthuav dav, qhov tsis zoo ntawm lub ntsej muag ntawm lub workpiece, thiab hnav ntau dhau ntawm lub laum me ntsis, thiaj li tiv thaiv kev cuam tshuam rau qhov zoo ntawm cov drilling thiab nce kev ua haujlwm nqi. Cov txuj ci hauv qab no yuav tsum ua kom ntseeg tau kom deb li sai tau:

- - Kev ntsuas qhov tseeb: qhov tseeb ntawm lub taub thiab qhov tob ntawm lub qhov;

- - Cov duab zoo: lub qhov roundness, cylindricity thiab axis ncaj;

- - Txoj hauj lwm tseeb: qhov coaxiality ntawm lub qhov thiab lub axis ntawm lub qhov lossis lub axis ntawm lub voj sab nraud; qhov sib thooj thiab qhov sib txuam ntawm lub qhov thiab lub qhov los yog lub qhov thiab lwm qhov chaw, thiab lwm yam.

Nyob rau tib lub sijhawm, 5 lub ntsiab lus hauv qab no tseem yuav tsum txiav txim siab:

- - Cov qauv ntawm lub qhov tob thiab kam rau ua qhov saum npoo roughness qhov;

- - Cov yam ntxwv ntawm kev ua haujlwm, suav nrog kev ruaj khov ntawm clamping overhang thiab rotatability;

- - Lub zog ceev, qhov system txias thiab ruaj khov ntawm cov cuab yeej tshuab;

- - Ua cov khoom tiav;

- - Cov nqi khiav lag luam;

Txawv Muaj ntau hom Drilling Machining - Cnc Drilling Cov Kev Pab Muaj Los Ntawm Minghe

Ntau qhov ntawm cov pwm, xws li cov ntsia hlau qhov, ntsia hlau qhov, tus pin lub qhov, lub qhov taub mandrel, puag ncig lub qhov raug kho qhov, thiab lwm yam, yuav tsum tau muab tshau thiab rov ua kom tau raws li qhov yuav tsum tau ua ntawm lub qhov taub, lub suab suab qhov tseeb thiab qhov ntxhib.

Cov txheej txheem nquag siv tau qhia rau hauv lub rooj.

| hom | Cov ntsiab lus |

| Ib Feem Drilling | Tib ntu siv ua luam tawm ncaj qha raws li qhov cim cim txoj haujlwm |

| Laib Tsav | Tho qhov nyob rau hauv ib ntu ua ntej, thiab siv qhov no ua cov taw qhia rau tho qhov nyob rau lwm qhov chaw. Ib ntu tuaj yeem siv rau kev tho ncaj qha hauv qhov rov qab thaum drilling; nws tseem tuaj yeem ua rau lub qhov laum kom qhov kev coj ua rov qab. |

| Tshuab Ua Si Drilling | Txhawm rau kom ntseeg tau tias lub qhov nrug deb ntawm ntu, ob ntu tuaj yeem clamped nrog cov chucks mus tib seem lossis ua ke nrog screws los tsim ib tus lej, thiab lub qhov tuaj yeem ua rau tib lub sijhawm raws li cim cim. |

Rov Ntsuas Cov Machining

Feem ntau muaj qee qhov pin qhov, ejector qhov, tub ntxhais kho qhov, thiab lwm yam hauv cov pwm uas yuav tsum tau ua tom qab kev sau ntawv lossis thaum sib dhos. Qhov kev ua tiav raug yog feem ntau IT6 rau IT8, thiab qhov roughness tsis tsawg dua Ra3.2μm.

Cov Qauv Tseem Ceeb Ntawm Kev Rov Ua Haujlwm

| hom | Cov ntsiab lus | |

| Lub cheeb workpiece | Nqus thiab reamed los ntawm fitter | |

| 10 ~ 20 | Ua los ntawm drilling, countersinking, reaming, thiab lwm yam. | |

| > 20 | Ua ntej tswj los ntawm fitter laum, tom qab ntawd milling thiab tho txawv tshuab ua | |

| Yuav tsum tau tua kom lub qhov | Thaum rov ua dua, ntau npaum li cas ntawm kev sib tsoo yuav tsum yog 0.02 ~ 0.03. Lub qhov yuav tsum tiv thaiv thaum kho cua sov thiab yuav rov ua av dua thaum sib sau ua ke | |

| Kev sib txuas ua ke ntawm cov khoom siv sib txawv | Thaum rov ua dua seem ntawm cov khoom sib txawv, reaming yuav tsum ua los ntawm cov ntaub ntawv nyuaj | |

| Hardening kho vajtse reaming | Los ntawm lub qhov rov ua dua ntawm cov khoom siv tawv tawv, ua ntej xyuas seb lub qhov puas tau deformed, reaming nrog tus qauv cemented carbide reamer, lossis rov ua dua nrog lub qub reamer, thiab tom qab ntawd siv cov cam khwb cia hlau sib tsoo qws los tsoo rau qhov loj me uas yuav tsum tau ua. | |

| Hu ua lub qhov | Thaum lub qhov rov tsis tau ua dua tshiab, lub qhov tob ntawm lub qhov taub yuav tsum sib sib zog nqus, tawm qhov ntev ntawm kev txiav ib feem ntawm cov khoom siv rov ua kom paub tseeb tias lub zoo ntawm lub qhov taub; nws tseem tuaj yeem tsim kho dua tshiab nrog tus qauv reamer, thiab tom qab ntawd rov mus ua dua lub qhov nrog lub qub reamer uas muaj hauv av txiav ntu. Unhinged hauv qab | |

| Tshuab xaws | Tom qab qhov chaw ua haujlwm tau clamped ib zaug, drilling, countersinking, thiab reaming tau nqa tawm tsis tu ncua kom ntseeg tau cov khoom sib luag thiab sib luag ntawm lub qhov | |

Sib sib zog nqus Qhov Machining

Cov cua txias channel qhov, rhaub qhov thiab ib feem ntawm lub ejector tus pin qhov hauv cov yas pwm yuav tsum ua kom tob-ua txoj haujlwm. Feem ntau, qhov tseeb ntawm qhov dej txias rau lub qhov dej tsis siab, tab sis nws yog qhov tsim nyog los tiv thaiv kev poob siab; txhawm rau kom paub tseeb tias lub tshav kub hloov mus ua haujlwm zoo, lub rhaub lub qhov muaj qee yam yuav tsum muaj rau lub qhov taub thiab qhov ntxhib, lub qhov taub yog 0.1 mm 0.3mm loj dua lub pas nrig cua sov, thiab qhov roughness yog Ra12.5 ~ 6.3 μm; thaum lub ejector lub qhov yuav tsum tau muaj theem siab dua, qhov tseeb ntawm qhov tseeb yog IT8 thiab muaj cov tseev kom muaj feem ntsug thiab ntxhib.

Ua cov qhov

Ntau qhov nyob rau hauv lub pwm yuav tsum kom ntseeg tau lub qhov nrug, lub qhov taub nyob deb li cas, parallelism ntawm lub axis ntawm txhua qhov, txiav kom mus rau lub ntsej muag kawg, thiab coaxiality ntawm lub qhov tom qab ob ntu sib dhos. Hom ntawm lub qhov system no feem ntau ua ntej, thiab tom qab ntawd lub qhov yog ua los ntawm kev sau ntawv.

Xaiv Cov Txheej Txheem Zoo Tshaj Plaws Drilling

Tom qab xyuas cov npe ntawm Cov Kev Pab Kho Mob saum npoo av, xaiv cov txheej txheem raws li kev txiav txim siab tseem ceeb, zoo li lub sijhawm tsim tawm, nqi tsim khoom, ib feem kam rau ua, ua siab ntev thiab siv. High-tolerance CNC milling, tig qhov tsis pom zoo kom thov cov theem nrab hlau saum npoo tiav, vim hais tias cov kev kho yuav hloov qhov ntau thiab tsawg ntawm cov khoom tiav los ntawm kev tshem tawm lossis ntxiv cov khoom me me.

Tiv tauj peb lossis Email sales@hmminghe.com txhawm rau saib peb cov neeg li cas, cov cuab yeej siv thiab cov cuab yeej siv tau tuaj yeem nqa cov khoom lag luam zoo rau tus nqi zoo tshaj plaws rau koj qhov project drilling.