Online Quote CNC Machining Kev Pabcuam

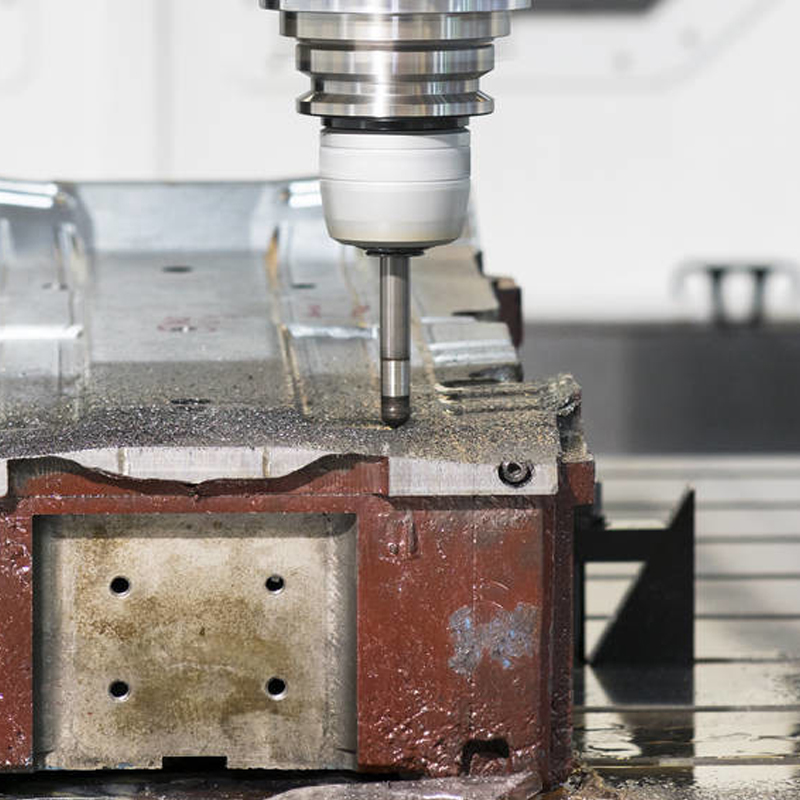

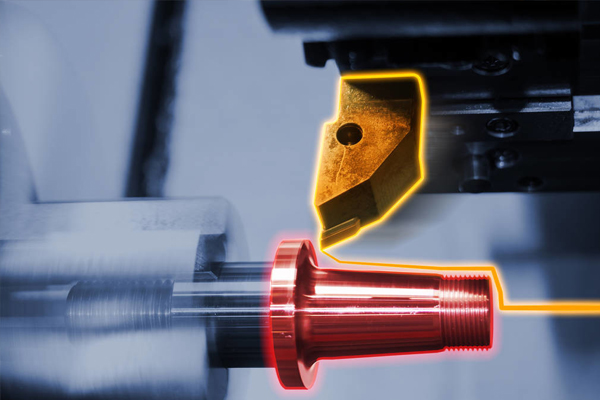

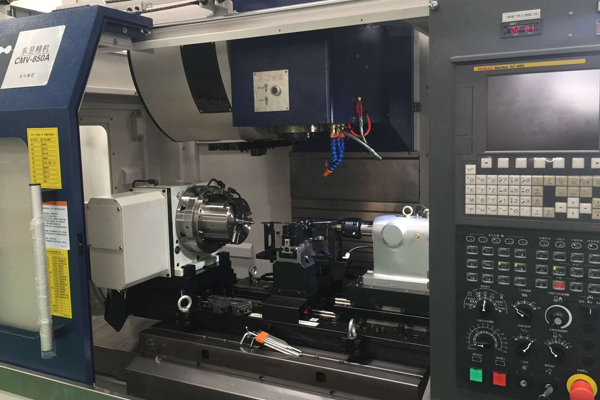

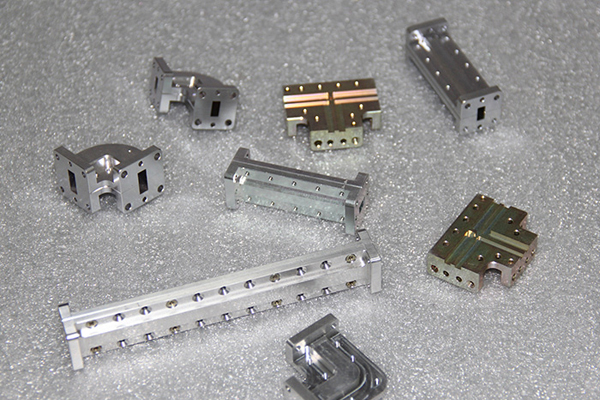

Minghe muaj nyob rau hauv-lub tsev CNC machining raws li kev ua tiav rau peb qhov kev pabcuam casting tuag. Cov tshuab CNC no siv cov txheej txheem txiav los tsim kev cai tsim khoom uas npaj rau kev sib dhos khoom.

Xav kom luv cov voj voog ntau lawm thiab txo tus nqi ntawm koj cov khoom siv tshuab? Sib xyaw ua ke ntau thev naus laus zis, CNC Machining Cov kev pabcuam tuaj yeem ua kom yooj yim rau txoj kev tsim khoom thiab ua kom lub nrawm loj ntau lawm cov tshuab hauv lub cav, thiab ua tiav cov qib siab ntawm qhov tseeb.Minghe muab ceev ceev online CNC machining raws li cov neeg siv. Xa koj cov ntaub ntawv CAD lossis nug rau peb, ceev ceev ceev CNC Cheeb Tsam cov lus cim yuav rov qab.

Txawm hais tias nws lub siab nrawm lossis cov qauv tsim khoom loj, peb muaj txoj cai CNC machining kev xaiv kom tau raws li qhov xav tau ntawm ob qho hlau thiab casting qhov chaw. Tau koj tej yaam num rau hauv kev siv lub sijhawm luv tshaj plaws.

Vim li cas Xaiv Tuam Tshoj Cnc Machining Kev?

Ntau tus neeg muas zaub xaiv Tuam Tshoj cov kev pabcuam, tab sis tsuas yog saib xyuas ob lub ntsiab lus: tus nqi qis thiab zoo kom tau raws li lawv cov kev xav tau. Tab sis nrog txoj kev txhim kho ntxiv ntawm kev lag luam thoob ntiaj teb, tus nqi tsis yog kev txhim kho ntxiv rau kev ntsuas tus neeg ua haujlwm tsim nyog.

Txawm hais tias Nyijpooj thiab Yelemes muaj cov thev naus laus zis ntau ntxiv txog kev tsim kho tshiab thiab kev tsim qauv muaj peev xwm, koj tuaj yeem tau txais kev muaj peev xwm zoo tshaj plaws los ntawm kev xaiv Tuam Tshoj CNC ua haujlwm pabcuam.

Ntawm Minghe, peb tau them nyiaj ntau rau kev ua siab ncaj thiab zoo. CNC machining yog tsuas yog ib qeb me me ntawm peb lub tuam txhab, peb them ntau dua rau cov paub tab thiab kev koom tes ntev.

Minghe muab koj lub peev xwm ua ntau lawm thiab muaj ntau lub peev xwm machining rau EDM qhov chaw nrog txawm tias qhov nruj tshaj plaws kev tso siab, feem ntau cov qauv hauv kev ntsuas, lossis cov txheej txheem tsim.

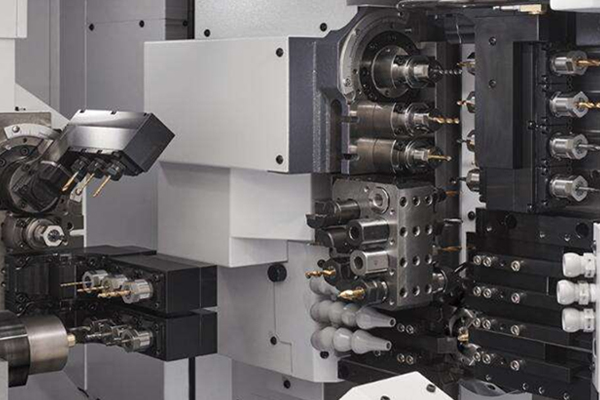

CNC Machining Kev Muaj Peev Xwm

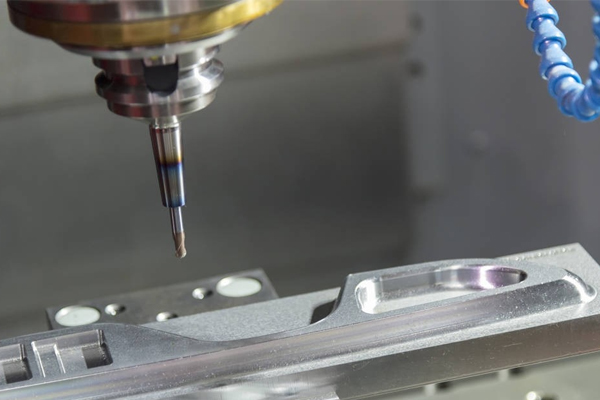

Raws li ib qho ntawm kev loj hlob ceev tshaj plaws kev pabcuam kev tsim khoom Tuam Tshoj cov chaw muag khoom thiab tuag casting tuam txhab, cov hauv qab no machining muaj peev xwm ntawm Minghe yog muaj los pab koj cov kev xav tau ntawm CNC machined qhov chaw, los ntawm kev tawm sai rau precision qhov chaw thiab cov cuab yeej machining, kom kawg siv ntau lawm.

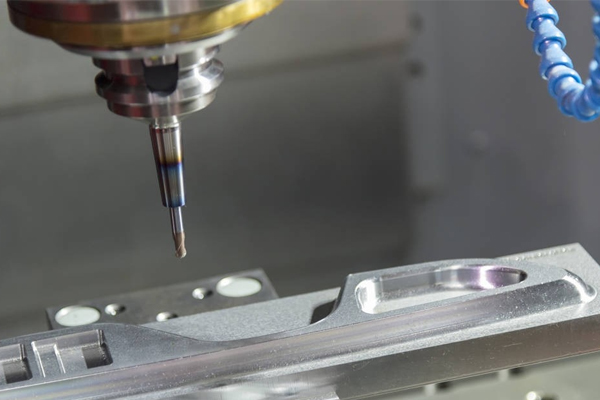

| Siv Lub Tshuab Milling |

| CNC milling siv los ua cov txheej txheem ua ntu. |

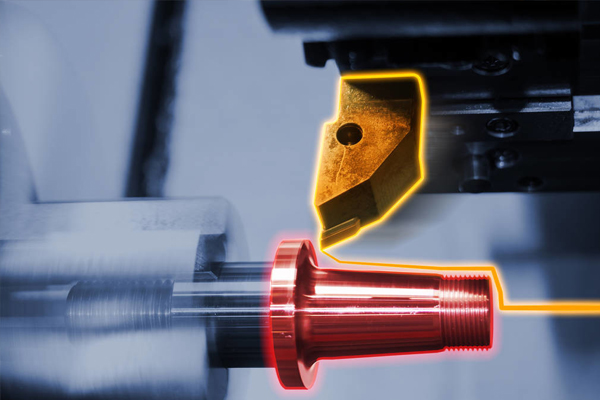

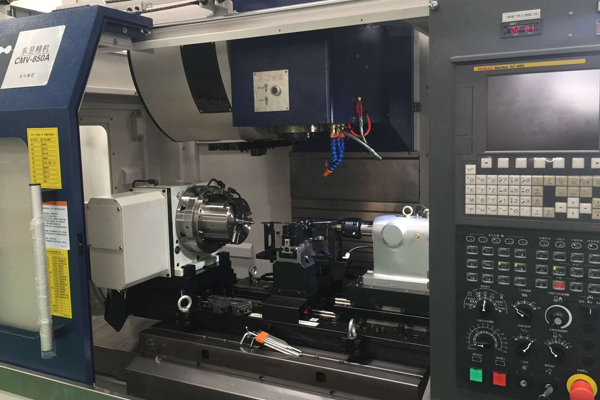

| Cnc Raws |

| CNC Raws feem ntau siv toolling los tig cov haujlwm ua haujlwm |

| Swiss Machining |

| Nws yuav raug siv los machining cov qhov me me hauv qhov tuav |

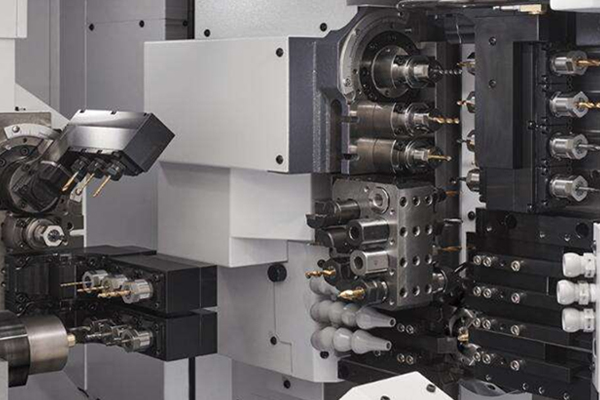

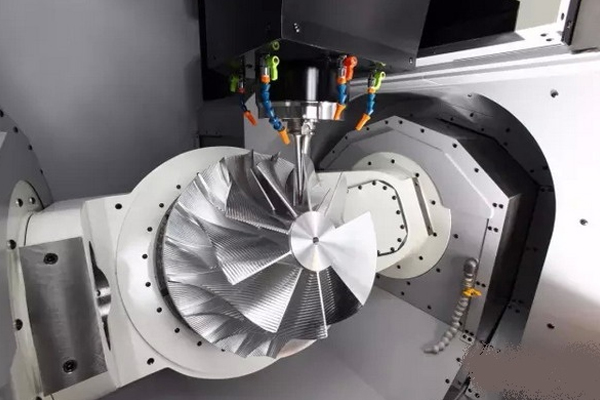

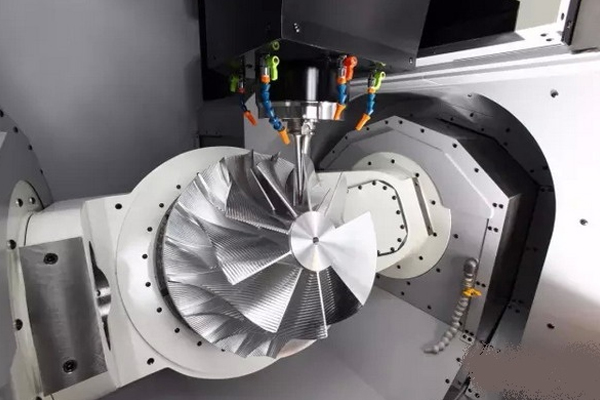

| 5 Axis Machining |

| Feem ntau siv los ua txheej txheem ntau seem. |

| Ntsug Machining |

| Tsim Kev Raug Tsav rau cov rooj zaum, discs, pwm thiab plhaub me me |

| Kab rov tav Machining |

| Tsim kom muaj tseeb Milling los ntawm ntxaiv kab rov tav layout mechanism |

Tuam Tshoj Minghe CNC Machining Khoom

Minghe CNC Machining kev pabcuam ua haujlwm nrog Conventional Alloy 、 Super Alloy thiab yas.

| Tshuaj Alloy |

- Aluminium: 2024, 5083, 6061, 6063, 7050, 7075, thiab lwm yam.

- Alloy: tooj dag 360, 101 tooj liab, 110 tooj liab, 932 tooj dag, zinc, thiab lwm yam.

- Titanium: qeb 2, qeb 5, thiab lwm yam.

- Stainless hlau: 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, thiab lwm yam.

- Hlau: 4140, 4130, A36, 1018, thiab lwm yam.

|

| Super Alloy |

- Greek Ascology / Carp 49

- Kab mob

- Nitronic 60

- Hwm 80

- Tej hub Matrix

- Inconel / Monel / Tuam Hlau

- Cov

|

| Yas Machining |

- POM (Delrin), ABS (Acrylonitrile Butadiene Styrene), HDPE

- Nylon, PLA, PC (Polycarbonate)

- SAIB (Polyether Ether Ketone)

- PMMA (Polymethyl Methacrylate lossis Acrylic)

- PP (polypropylene)

- PTFE (Polytetrafluoroethylene), thiab lwm yam.

|

Tuam Tshoj Minghe Nto Tiav

Koj tuaj yeem xaiv cov kev xaiv dav hlau ua tiav cov kev pab cuam tom qab machining ntawm Minghe CNC machining lossis tuag casting chaw tsim tshuaj paus txhawm rau txhim kho qhov chaw zoo li, qhov chaw du, kev tiv thaiv corrosion thiab lwm yam kev ua tau zoo ntawm koj CNC machined qhov chaw.

| Electroplating / Plating ▶ |

| Hmoov txheej / Hmoov txheej ▶ |

| Bead blasting / Hlaws tawg ▶ |

| Abrasive blasting / sandblasting▶ |

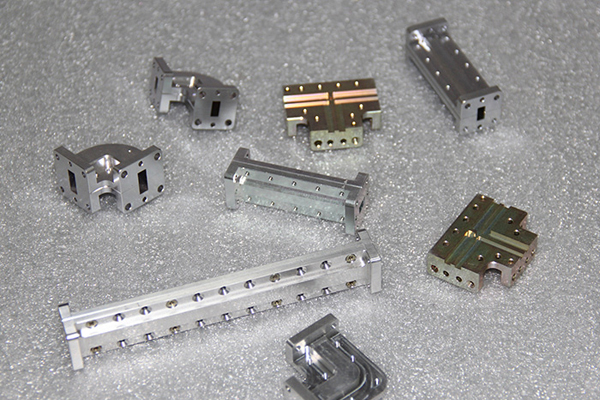

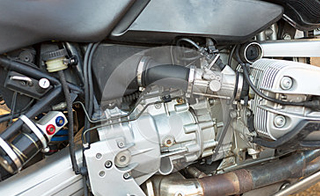

Cov ntawv thov ntawm MINGHE CNC Machining Services

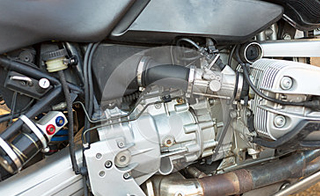

CNC machining qhov chaw nyob ib puag ncig koj, lawv yuav yog qhov tseem ceeb ntawm koj lub tsheb thiab kuj tuaj yeem ua lub luag haujlwm tseem ceeb hauv koj cov khoom siv hluav taws xob. Minghe yog qhov ua tiav CNC tsum uas tau koom nrog ntau yam ntawm CNC machining kev siv.

Peb qhov chaw tsim khoom tsim nyog rau kev lag luam hauv qab no:

|

CAW KAWG

KEV LAG LUAM |

|

TSO

KEV LAG LUAM |

|

TSHUAB

KEV LAG LUAM |

|

LED TEEB

KEV LAG LUAM |

|

HEATSINK

KEV LAG LUAM |

|

CHAW UA HAUJ LWM

KEV LAG LUAM |

|

TWJ YEEM VALVE

KEV LAG LUAM

|

|

TSHUAJ NTXIV

KEV LAG LUAM

|

|

PHEEJ

KEV LAG LUAM

|

|

KEV THEM NYIAJ YUG

KEV LAG LUAM

|

|

AEROSPACE

KEV LAG LUAM

|

|

KEV HAUV FAIS FAB

KEV LAG LUAM

|

|

ZOO TSHAJ PLAWS

KEV LAG LUAM

|

|

ROBOTS

KEV LAG LUAM

|

|

NTXIV

KEV LAG LUAM

|

Qhov Zoo ntawm Minghe CNC Machining Kev Pabcuam

- Npaum CNC machining Suav teb Hoobkas rau ntau lawm ceev prototyping pab

- Qhov nruab nrab 7 hnub hloov pauv lub sijhawm thiab 99.85% raws sijhawm

- Kev xaiv ntau ntawm cov ntaub ntawv machining kom tau raws li cov khoom tshwj xeeb.

- Kev xa xov pub dawb nyob rau hauv 24 teev tom qab kev nug

- Siab cov neeg siv khoom txaus siab thiab muaj kev ntseeg siab

- Kev tsim kev nplua nuj thiab kev paub khoom

- automation yog nce ntxiv.

- Tsawg heev uas tsis

- Peb cov kev pabcuam yog tus nqi zoo.

- Qhov Ntim: 1-20 + seem

- Xam los ntawm: Hauv 24 teev

- Lub Sij Hawm Ua: Hauv nrawm li 3 hnub

- Cov Khoom Siv: cov hlau thiab cov yas

- Qhov loj me: Suav txij li 10 hauv. X 7 hauv. X 3.75 hauv. Txog 22 in. X 14 hauv. X 1.25 hauv

- Txheeb Toomrances: +/- 0.1 hli