Tsawg Tus Nqi Casting

Qhov Tsawg Tshaj Tawm Casting

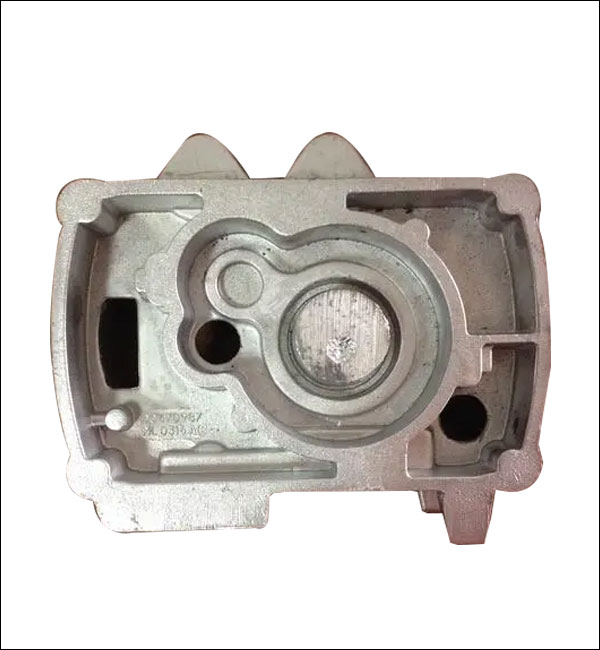

Kev tawm suab siab tsawg txhais tau hais tias lub pwm feem ntau tso rau saum cov roj ntim kaw, thiab cov cua nrawm nkag mus rau hauv qhov ua kom tawg kom ua rau lub nrawm qis (0.06 ~ 0.15MPa) ntawm nplaim molten hlau, yog li hlau molten nce los ntawm riser yeeb nkab txhawm rau txhawm rau txhawm rau pwm thiab tswj Tau Yooj yim casting txoj kev. Qhov txheej txheem casting no tau zoo rau kev pub mis thiab kev ua haujlwm me me. Nws yog qhov yooj yim rau qhov cam loj thiab nyias-walled complex castings yam tsis muaj risers, thiab tus nqi hlau rov qab tuaj yeem ncav cuag 95%. Tsis muaj kuab lom, yooj yim kom paub cov automation. Txawm li cas los xij, cov cuab yeej siv tus nqi yog siab thiab qhov ua tau zoo yog tsawg. Feem ntau siv rau casting cov hlau tsis muaj txhuas cov ntawv ci.

Tsawg-siab casting yog cov txheej txheem casting nyob rau hauv uas cov kua ua kua yog nias rau hauv cov pwm kab noj hniav txij hauv qab mus rau sab saum toj siab, thiab solidified nyob rau hauv siab kom tau castings. Lub hau kaw tau ntim nrog huab cua qhuav lossis roj inert. Nrog kev pab los ntawm lub siab ua nyob rau ntawm lub ntsej muag hlau molten, hlau molten tuaj rau pwm kom du raws cov riser yeeb nkab los ntawm hauv qab mus rau sab saum toj los ntawm kev sib tw khiav. Tus puv filling feem ntau yog 20 ~ 60kPa. Thaum cov casting ua tiav tag nrho, cov pa roj rau qhov ua kua ntawm qhov chaw tso tawm, yog li cov hlau tsis muaj hlau nyob hauv riser cov yeeb nkab thiab tus dej ntws tawm mus rau hauv qhov chaw raug ntsia los ntawm nws tus kheej qhov hnyav, tom qab ntawd pwm qhib thiab lub casting yog nqa tawm.

Cov txheej txheem ntau lawm ntawm kev kub siab casting suav nrog plaub tus txheej txheem hauv qab no:

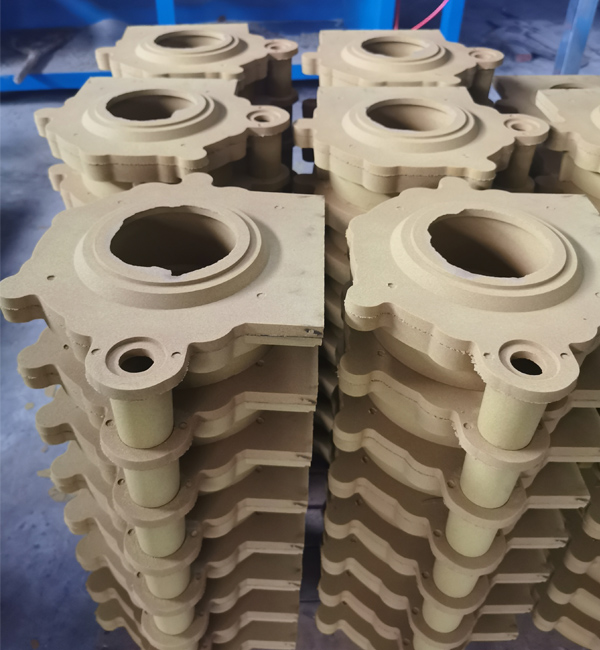

- - Hlau smelting thiab kev npaj pwm lossis ua pwm pwm.

- - Npaj ua ntej nchuav: suav nrog crucible sealing (haum sealing npog), slag tshem tawm hauv riser yeeb nkab, ntsuas qib kua, ntsuas qhov ntsuas, ntsuas mould, zawm pwm lossis pwm, thiab lwm yam.

- - Ncuav: suav nrog kev ua kom muaj kua, txhaws, ua pa taws, sib kis, hloov siab thiab ua kom txias, thiab lwm yam.

- - Demoulding: suav nrog xoob molding thiab casting tawm.

Daim Ntawv Thov ntawm Kev Siv Hluav Taws Xob Siab

Lub tshuab nqus dej qis qis qis tshaj yog thaum ntxov tshaj tawm kev tiv thaiv kev sib tsoo lub tshuab, thiab nws tau siv rau hauv kev lag luam tsim txij xyoo 1940 los. Lub suab qis qis casting yog qhov yooj yim tuag casting, thiab cov ntu tsis tawg tuaj yeem siv cov txheej txheem no. Tam sim no, lub tshuab nqus qis qis yog siv los tsim cov khoom siv aluminium hlau thiab cov hlau nplaum hlau qhov chaw, xws li lub log tsheb hauv kev lag luam tsheb, lub tog raj kheej lub tog raj kheej, lub tog raj kheej, rab phom, lub plhaub mos txwv, cov tsis sib haum, cua qhia lub log thiab lwm cov hlau nrum nrog cov duab sib tov thiab cov khoom lag luam siab nyob rau hauv kev lag luam tsheb.Thaum tsis tshua muaj siab casting siv los tsim cov hlau nrum, xws li cov cam khwb cia cov hlau, cov riser yeeb nkab yuav tsum tau ua cov khoom siv tshwj xeeb refractory. Tsis tshua muaj siab casting tseem tuaj yeem siv rau cov tooj liab me me ntawm cov hlau nplaum, xws li cov yeeb nkab fawm yeeb, cov kais dej tso rau hauv chav da dej, thiab lwm yam.

Cov Nta Ntawm Luv Siab Casting

Lub tshuab nqus qis tsis tuaj yeem siv cov xuab zeb, hlau, graphite, thiab lwm yam. Cov txheej txheem txhaws yog txawv ntawm lub ntiajteb txawj nqus casting xws li cov hlau nrum thiab cov xuab zeb casting, thiab nws kuj tseem txawv los ntawm kev nrum casting nrog kev kub siab thiab siab ceev txhaws. Nws muaj cov zoo li nram no:

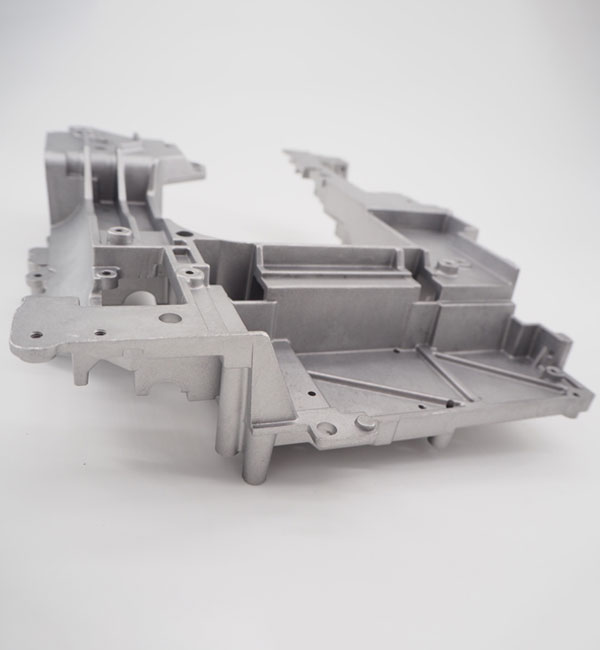

- - Txhaws nrog molten hlau ntshiab txhim kho qhov huv huv ntawm castings. Txij li thaum lub molten slag feem ntau ntab saum nplaim molten hlau, lub suab qis qis uas tau ntim nrog lub hlau molten nyob rau hauv qhov chaw qis ntawm crucible los ntawm riser yeeb nkab, uas ua kom tsis txhob muaj qhov molten slag nkag mus rau cov pwm kab noj hniav. Cov.

- - Lub tshuab ua kua hlau ua haujlwm ruaj khov, txo lossis zam qhov cuam tshuam, cuam tshuam thiab txaws ntawm cov kua hlau thaum sau, yog li txo qhov tsim ntawm oxidized slag.

- - Tus casting muaj zoo qauv. Lub hlau molten yog qhov puv ntom nti, tuaj yeem txhim kho qhov kev npliag ntawm cov hlau molten, uas muaj txiaj ntsig zoo rau kev tsim cov nruas nrog cov ntshiab qhov thaiv thiab qhov chaw du, thiab tau txais txiaj ntsig ntau dua rau qhov tsim ntawm cov nyias-walled castings.

- - Lub casting crystallizes thiab solidifies nyob rau hauv lub siab, uas tuaj yeem ua kom tiav thiab cov qauv casting yog tuab.

- - Txhim kho cov paib ntawm molten hlau. Nyob rau hauv ib txwm muaj xwm txheej, tsis tas yuav muaj riser, thiab cov hlau tsis muaj qhov tsis txaus nyob rau hauv cov yeeb nkab riser tuaj yeem rov rau tus crucible rau rov siv dua, uas zoo heev txhim kho qhov tawm ntawm molten hlau. Feem ntau mus txog 90%,

- - Kev tsim khoom thiab kev ua haujlwm zoo, kev ua haujlwm zoo, kev ua haujlwm siab ntau lawm, yooj yim rau kev paub txog kev siv tshuab thiab siv tshuab,

- -Qhov siab casting tseem muaj qee qhov tsis xws luag, khoom siv thiab pwm tso peev kuj tseem loj; nyob rau hauv kev tsim cov hlau aluminium castings, lub crucible thiab riser cov yeeb nkab tau nyob rau hauv kev sib cuag nrog lub hlau tsis ntev ntev, uas yog kev cuam tshuam rau kev xeb thiab khawb, uas tseem yuav ua rau cov hlau molten kom cov hlau thiab ua kom tsis zoo.

Txawv Ntau Hom Pauv Muaj Zog Ntawm Kev Ntsuas Cov Hluav Taws Xob Uas Tsis Zoo

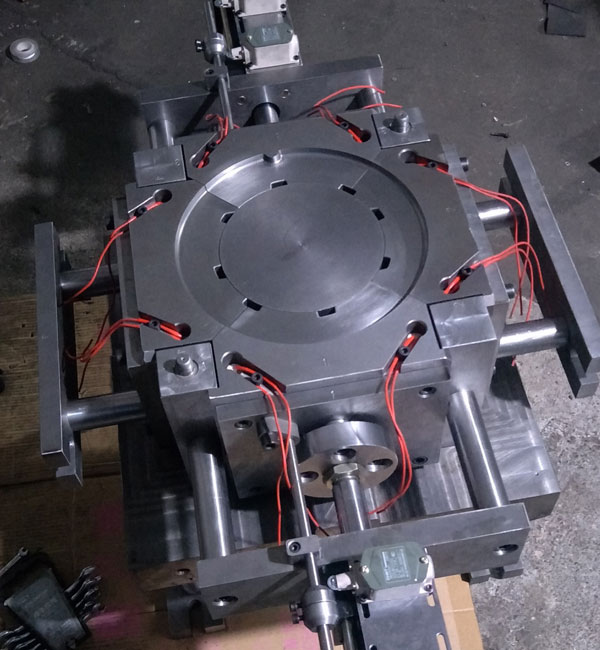

Minghe ib txwm ua raws li cov neeg siv cov kev xav tau thiab lub tuam txhab cov qauv kev pabcuam. Txhua qhov txuas ntawm pwm tsim, pwm kev sib dhos, pwm debugging, pwm kev sim, pwm txheej txheem, thiab lwm yam, muaj cov kws ua haujlwm siab kom koj nyob hauv xov tooj;

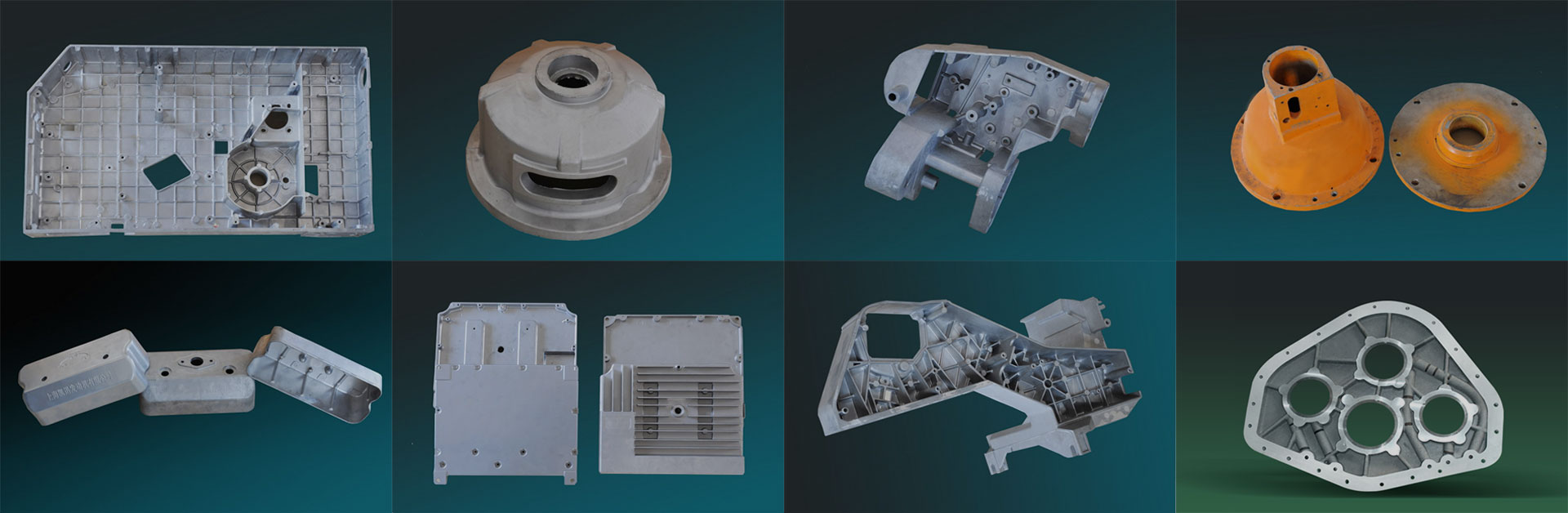

| Tsis tshua muaj siab Castings Kav Khw 1 ▶ |

| Tsis tshua muaj siab Castings Kav Khw 2 ▶ |

| Tsis tshua muaj siab Castings Kav Khw 3 ▶ |

| Tsis tshua muaj siab Castings Kav Khw 4▶ |

| Tsis tshua muaj siab Castings Kav Khw 5▶ |

| Multifunctional drilling thiab tapping tshuab▶ |

| Aluminium alloy khoom quenching-tempering khoom ▶ |

| De-rooj hydraulic xovxwm▶ |

| Rauv▶ |

| Tsis tshua muaj siab nchuav cov khoom-tub ntxhais plhaub tshuab▶ |

| Tsis tshua muaj siab nchuav tshuab▶ |

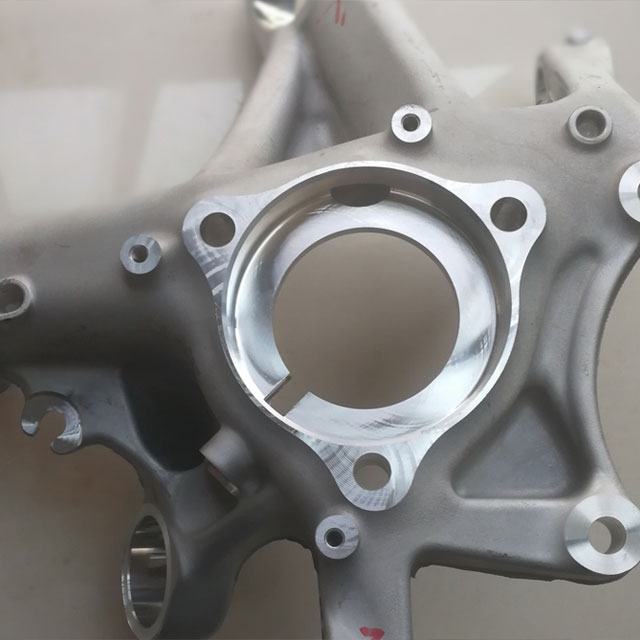

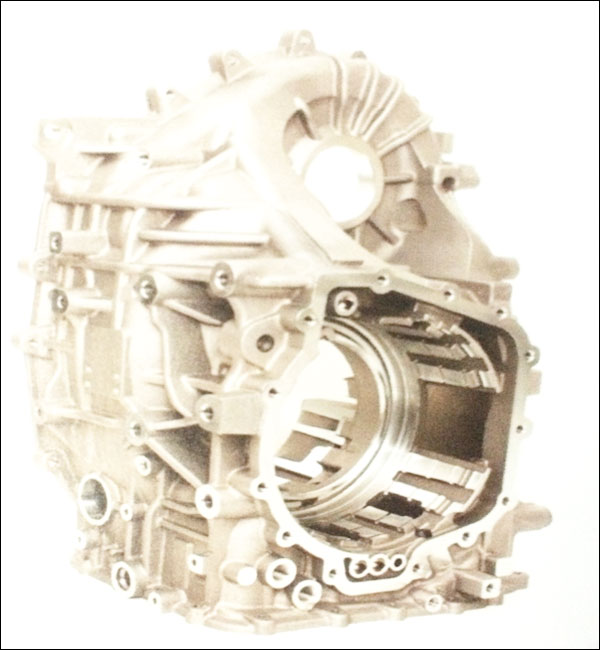

| Tsawg-siab casting khoom-gearbox lub cev▶ |

Minghe Cov Kev Kawm Txog Qhov Tsis Tshua Cov Hluav Taws Xob Casting

Minghe Casting fabrication kev pabcuam yog muaj rau ob tus qauv tsim rau kev muaj tiag thiab qis rau siab ntim ntau lawm khiav ntawm koj qhov tuag casting qhov chaw, pob zeb casting seem, peev casting seem, hlau casting seem, poob ua npuas casting qhov chaw thiab ntau dua.

Mus Saib Ntau Cov Luam Hauv Qhov Chaw Kawm >>>

Xaiv Qhov Zoo Tshaj Plaws Tshaj Tawm Cov Khoom Siv

Tam sim no, peb lub suab qis qis qis raug xa tawm mus rau Asmeskas, Canada, Australia, United Kingdom, Lub Tebchaws Yelemees, Fabkis, Sout Africa, thiab ntau lub tebchaws nyob thoob qab ntuj. Peb yog ISO9001-2015 sau npe thiab tseem tau ntawv pov thawj los ntawm SGS.

Peb cov kev cai qis siab casting fabrication kev pabcuam muab cov khoom lag luam ruaj khov thiab pheej yig uas ua tau raws li koj cov kev qhia tshwj xeeb rau kev kho tsheb, kev kho mob, huab cua, hluav taws xob, khoom noj khoom haus, kev tsim kho, kev ruaj ntseg, tubrog nkoj, thiab ntau dua kev lag luam. Cauj xa koj qhov kev nug lossis xa koj cov duab kos kom tau txais nqe lus dawb hauv lub sijhawm luv.Paj rau peb lossis Email kev muag khoom@hmminghe.com txhawm rau saib peb cov neeg li cas, cov cuab yeej siv thiab cov cuab yeej tsim tawm tuaj yeem nqa qhov zoo tshaj plaws rau tus nqi zoo tshaj plaws rau koj lub phiaj xwm qis ua haujlwm siab.

Peb Muab Cov Kev Pab Cuam Uas Tau Xam Pom:

Minghe Casting cov kev pabcuam ua haujlwm nrog xuab zeb casting casting hlau casting 、 peev casting ploj ua npuas ncauj casting, thiab lwm yam.

Xuab zeb Casting

Xuab zeb Casting yog cov txheej txheem ib txwm coj ua uas siv cov xuab zeb ua cov qauv ua qauv loj los ua cov pwm. Lub ntiajteb txawj nqus casting feem ntau yog siv rau cov xuab zeb tuaj pwm, thiab lub tshuab nqus dej siab qis, centrifugal casting thiab lwm cov txheej txheem tseem tuaj yeem siv thaum muaj cov kev xav tau tshwj xeeb. Cov txheej txheem xuab zeb muaj ntau yam ntawm kev yoog tau, cov ntawv me me, tej daim loj me, cov khoom yooj yim, cov khoom sib txuam, cov xaj thiab cov khoom loj tuaj yeem siv.

Permanent Mould Casting

Permanent Mould Casting muaj lub neej ntev thiab kev tsim khoom ntau lawm, tsis tsuas yog muaj qhov zoo qhov tseeb thiab qhov chaw du, tab sis kuj muaj lub zog siab dua li cov xuab zeb nrum thiab tsis tshua muaj kev puas tsuaj thaum tib lub hlau nchuav tau nchuav. Yog li no, nyob rau hauv kev lag luam huab hwm coj ntawm nruab nrab thiab me me tsis muaj hlau tsis zoo, ntev li ntev melting kis ntawm cov khoom siv casting tsis siab dhau, cov hlau casting feem ntau nyiam.

Peev Casting

Qhov loj tshaj kom zoo dua peev casting yog tias vim tias cov peev txheej ua lag luam muaj qhov siab dav thiab qhov chaw tiav, lawv tuaj yeem txo qhov kev ua haujlwm machining, tab sis tawm ntawm cov nyiaj machining me me rau ntawm qhov chaw nrog cov kev xav tau ntau dua. Nws tuaj yeem pom tias kev siv peev txheej txheej txheem tuaj yeem txuag ntau lub tshuab cuab yeej tshuab thiab ua haujlwm txiv neej-teev, thiab txuag tau cov ntaub ntawv nyoos hlau ntau.

Poob Ua Npuas Ncauj Casting

Poob ua npuas ncauj casting yog los sib txuas ua ke paraffin siv quav ciab lossis ua npuas ua qauv zoo ib yam li cov casting loj thiab cov duab mus rau hauv pawg pawg. Tom qab txhuam thiab ziab rov qab ua kom tiav txheej, lawv muab faus rau hauv cov xuab zeb quartz qhuav rau kev co qauv, thiab nchuav hauv qab qhov tsis zoo los ua kom cov qauv ua pa. , Lub tshuab ua kua hlau nyob hauv txoj haujlwm ntawm tus qauv thiab tsim qauv txheej txheem txheej tom qab ua kom ruaj khov thiab txias.

Tuag Casting

Kev tuag casting yog txheej txheem txheej txheem hlau, uas yog tus cwj pwm los ntawm kev thov kev kub siab rau lub tshuab hlau uas siv cov kab noj hniav ntawm cov pwm. Cov pwm feem ntau yog ua los ntawm qib siab-lub zog alloys, thiab cov txheej txheem no me ntsis zoo ib yam li kev txhaj tshuaj molding. Feem ntau cov hlau tuag yog hlau tsis xeb, xws li zinc, tooj, txhuas, magnesium, txhuas, yajthem, thiab txhuas-txhuas alloys thiab lawv cov alloys. Minghe tau ua Tuam Tshoj cov theem saum toj kawg nkaus tuag qhov kev pab cuam txij li thaum 1995.

Centrifugal Casting

Centrifugal Casting yog cov txheej txheem thiab cov txheej txheem ntawm kev txhaj tshuaj kua hlau rau hauv kev hloov pauv pwm siab, kom cov kua hlau ua lub zog yog lub zog centrifugal suab los txhawm rau txhawm rau pwm thiab tsim kev ua haujlwm. Vim los ntawm lub zog centrifugal zog, cov kua hlau ua kua tuaj yeem sau pwm pwm zoo rau hauv cov kev taw qhia radial thiab tsim dawb qhov chaw ntawm txoj haujlwm pov; nws cuam tshuam cov txheej txheem crystallization ntawm cov hlau, thiaj li txhim kho cov neeg kho tshuab thiab lub zog ntawm kev ua haujlwm.

Tsawg Tus Nqi Casting

Tsawg Tus Nqi Casting txhais tau hais tias lub pwm feem ntau tso rau saum cov ntsia ntawm crucible, thiab cov cua nrawm nkag mus rau hauv tus crucible ua rau kom muaj qhov ntsuas qis (0.06 ~ 0.15MPa) nyob rau saum npoo ntawm molten hlau, kom cov hlau molten sawv los ntawm cov yeeb nkab riser rau sau cov pwm thiab kev tswj xyuas Kev qhia ua yeeb yam. Qhov txheej txheem casting no muaj kev pub mis zoo thiab cov qauv ntom, yooj yim rau qhov loj dua-cov phab ntsa nyuaj ua si, tsis muaj tus ris, thiab tus nqi hlau rov qab yog 95%. Tsis muaj kuab paug, yooj yim kom paub cov automation.